In the ever-evolving landscape of mining and transportation, selecting the optimal Coal Haul Truck is crucial for maximizing efficiency and productivity. According to industry expert, John Smith, a veteran in haulage solutions, "Choosing the right Coal Haul Truck can significantly influence the operational success of a mining project." This statement resonates with many stakeholders in the industry, as the demands for reliable transportation methods continue to grow.

Understanding the specific needs of coal transportation is essential when navigating the myriad of options available on the market. Factors such as load capacity, terrain adaptability, and fuel efficiency play a pivotal role in ensuring that operations run smoothly. As the industry faces increasing pressure to meet both economic and environmental standards, the importance of selecting a trucks that align with operational requirements cannot be understated.

As this guide unfolds, we will delve into the critical considerations for choosing the best Coal Haul Truck tailored to your specific needs, ensuring you're equipped with the knowledge to make an informed decision that will ultimately enhance your operational workflow.

When selecting the right coal haul truck, it's essential to understand the various types available, as each is designed to meet specific operational demands. The most common categories of coal haul trucks include rigid trucks, articulated trucks, and underground trucks.

Rigid trucks are often preferred for their simplicity and stability on flat surfaces, making them ideal for open-pit mining operations where heavy loads are common. Their strong chassis and powerful engines allow them to efficiently transport large quantities of coal over short to medium distances.

On the other hand, articulated trucks provide enhanced maneuverability, which is beneficial in more challenging terrains or confined spaces. These trucks can navigate tight turns and steep inclines, making them suitable for underground coal mines or uneven ground conditions.

Underground trucks are specifically designed for subterranean operations, featuring a compact design and features that allow them to operate safely in limited headroom areas while ensuring efficient coal transport. Understanding these differences is crucial for operators to choose the right coal haul truck tailored to their specific requirements and operational environments.

When selecting the best coal haul truck for your operational needs, it’s crucial to focus on several key features that directly impact performance and efficiency. One of the primary considerations is the truck's payload capacity, which determines how much coal can be transported in a single trip. Choosing a vehicle that can handle your expected load without compromising on safety is essential. Additionally, look at the truck's engine power and fuel efficiency, as these factors will influence operational costs and overall productivity in the long run.

Another important aspect to consider is the truck's braking system and overall stability. Given the weight of coal and the conditions often encountered in mining environments, robust braking mechanisms and a well-designed suspension system are vital for ensuring operator safety and comfort. Furthermore, assess the truck’s durability and maintenance requirements, as a reliable vehicle reduces downtime and repair costs. By carefully evaluating these features, you can make an informed decision that aligns with your specific coal transport needs.

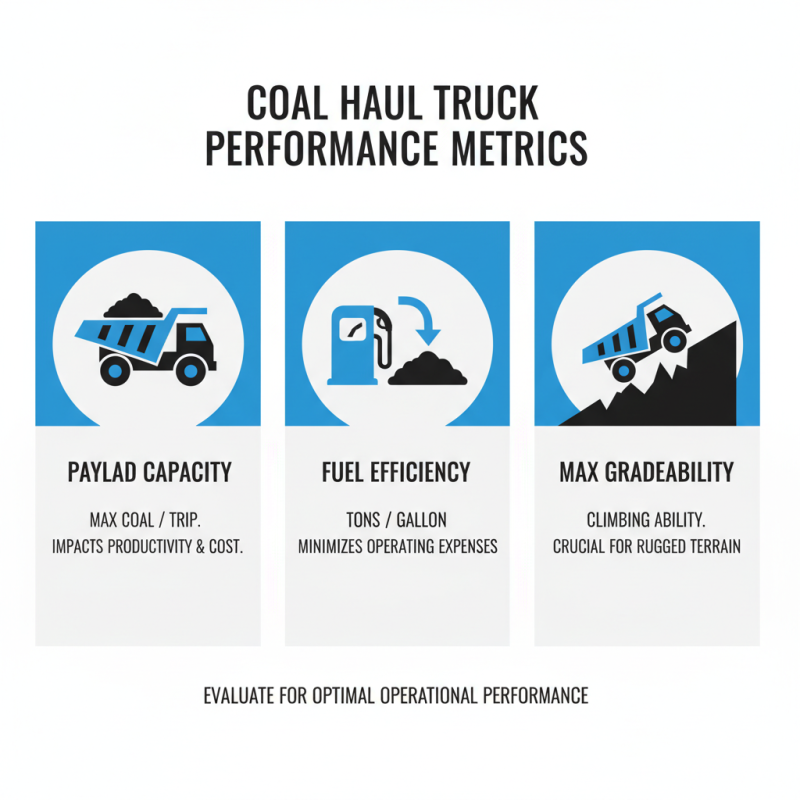

When choosing the best coal haul truck, evaluating performance metrics is paramount to ensure that the vehicle meets operational demands. Key performance metrics to consider include payload capacity, fuel efficiency, and maximum gradeability. Payload capacity determines how much coal can be transported in a single trip, which directly impacts productivity and operational cost. Fuel efficiency, measured in tons per gallon, reflects the effectiveness of the truck in converting fuel into hauling power and is crucial for minimizing operating expenses. Additionally, maximum gradeability indicates the truck's ability to navigate inclines, which is vital in the often rugged terrains typical of coal mining operations.

Another important aspect to examine is maintenance and durability. A truck that requires less frequent servicing can lead to reduced downtime and lower long-term costs. Metrics such as mean time between failures (MTBF) and service intervals are insightful indicators of reliability. Furthermore, advancements in technology, such as telematics systems, can provide real-time data on truck performance, allowing for better monitoring and proactive maintenance. Evaluating these performance metrics not only helps in making an informed decision but also aligns the truck’s capabilities with the specific needs of coal hauling operations, ensuring efficiency and effectiveness in logistics management.

When selecting a coal haul truck, safety and compliance must be top priorities. According to the Mine Safety and Health Administration (MSHA), in 2020 alone, mine operators reported over 1,000 safety violations related to equipment, with many stemming from inadequate maintenance or improper design. Therefore, ensuring that a truck meets rigorous safety standards is crucial. Compliance with these regulations not only safeguards the well-being of operators and workers but also enhances operational efficiency by reducing downtime due to accidents or inspections.

Moreover, the American National Standards Institute (ANSI) outlines a series of compliance benchmarks for heavy machinery, which must be adhered to in the coal industry. Recent statistics suggest that companies prioritizing compliance see a 30% reduction in injury rates compared to those that do not. This reveals that investing in trucks that meet or exceed these compliance standards can yield tangible benefits in terms of safety.

Additionally, features such as advanced braking systems, rollover protection, and stability assurance technology not only help in meeting these standards but also contribute to improved overall performance in challenging mining environments.

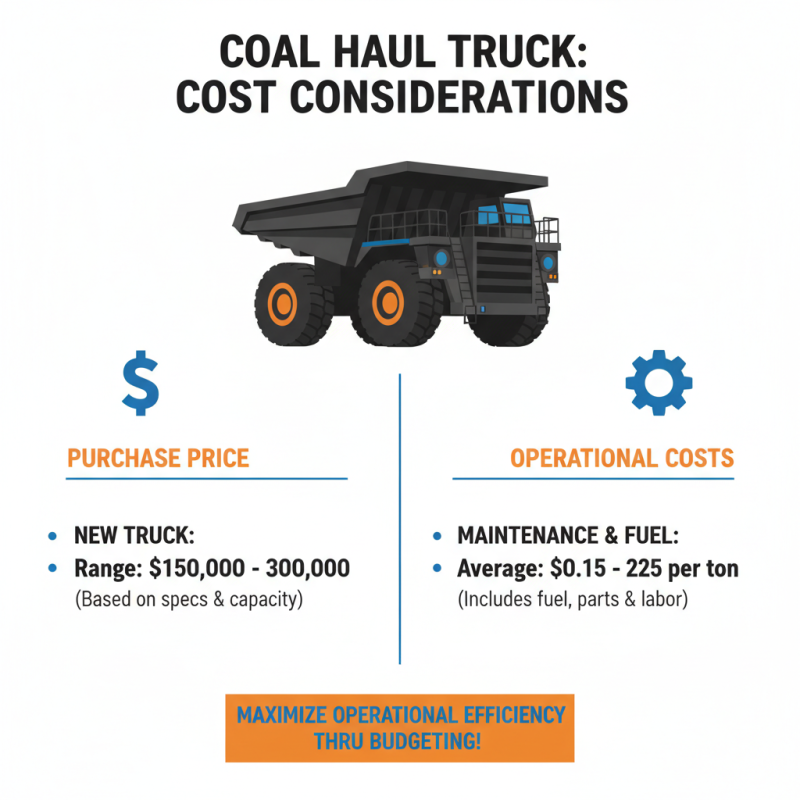

When considering the purchase of a coal haul truck, understanding the cost considerations and budgeting effectively is crucial for maximizing operational efficiency. According to industry reports, the price of new coal haul trucks can range significantly, typically between $150,000 and $300,000, depending on specifications and capacity. Additionally, maintenance and operational costs can average around $0.15 to $0.25 per ton of coal transported, which is an essential factor to include in your budgeting process.

Moreover, potential buyers should factor in additional expenses such as insurance, financing options, and potential customization needs which can further influence the overall cost. A report by a leading industry analyst suggests that operators should allocate at least 15% of the initial investment for annual maintenance and unexpected repairs. By conducting a detailed cost analysis that encompasses both upfront and ongoing costs, you can ensure a comprehensive understanding of the investment required for a coal haul truck. This strategic approach not only aids in financial planning but also contributes to a more efficient and sustainable operation in the coal transport sector.