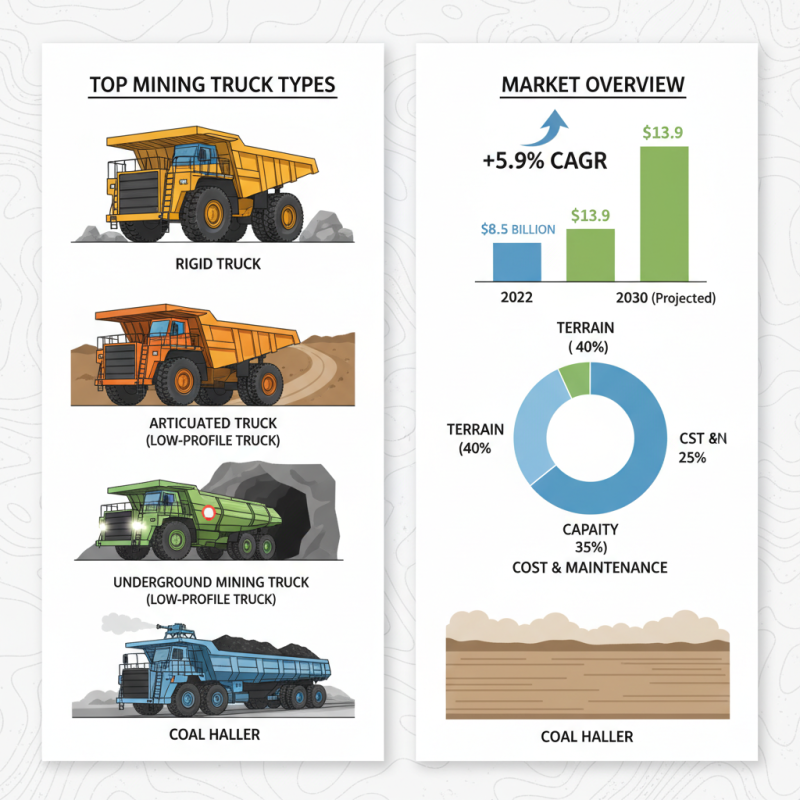

Mining trucks play a critical role in the mining industry. Understanding the various types of mining trucks is essential for efficiency. In 2022, the global mining truck market was valued at approximately $8.5 billion. This figure is projected to grow at a CAGR of 5.9% from 2023 to 2030.

Different types of mining trucks are designed for specific tasks. For instance, rigid trucks are robust, handling heavy loads. Articulated trucks, on the other hand, offer superior maneuverability. These trucks are crucial in accessing challenging terrains, yet not all mining operations utilize them effectively.

Still, the choice of the right type of mining truck isn't straightforward. Factors such as terrain, load capacity, and cost come into play. The wrong selection can lead to inefficient operations and increased maintenance costs. As mining methods evolve, companies must regularly reassess their choices. Understanding the types of mining trucks ensures that operations remain efficient and cost-effective.

Mining trucks play a crucial role in the mining industry. They are designed to transport heavy materials over rough terrain. These vehicles help move ores, coal, and other mined resources efficiently. They come in various types, each suited for different mining operations. Proper maintenance of these trucks is vital for operational uptime and safety.

The importance of mining trucks cannot be understated. They improve productivity and reduce manual labor. However, their fuel consumption can be high. This raises operational costs significantly. Mining companies must balance efficiency with sustainability. Some trucks are equipped with advanced technology to enhance performance. Yet, reliance on technology can sometimes lead to unanticipated issues. Regular training for operators can mitigate potential problems.

Safety is another critical aspect of using mining trucks. Due to their large size, they can present hazards. Operator error or machinery failure can lead to accidents. Implementing strict safety protocols is essential. Overall, while mining trucks are indispensable, they also present challenges. Awareness and careful management of these challenges are necessary for a successful mining operation.

This chart illustrates the weight capacity of various types of mining trucks commonly used in the industry. Understanding the capabilities of each type is crucial for effective operations and planning in mining projects.

Mining trucks play a crucial role in the extraction industry. Their size and load capacity significantly impact efficiency. Generally, these trucks can be categorized into three main types: light, medium, and heavy. Each type serves distinct operational needs, depending on the mining environment and material type.

Light-duty trucks are typically used for smaller, localized operations. They have a reduced load capacity, which can range from 10 to 20 tons. Though they are more maneuverable, they might not be suitable for all terrains. Medium trucks offer a balance, managing loads between 20 and 40 tons. They are often preferred for slightly larger operations, but their versatility can lead to overloading issues if not properly monitored.

Heavy trucks are the giants of the mining world. With the capability to transport payloads exceeding 40 tons, they are indispensable in large-scale mining operations. However, these trucks can struggle in confined spaces or steep terrains. Operators often face challenges regarding maintenance and fuel efficiency. Understanding these intricacies is essential for optimizing operations and minimizing costs. Inadequate planning can lead to wasted resources and increased downtime.

When choosing a mining truck, consider the key features that significantly impact performance and safety. Payload capacity is crucial. It dictates how much weight the truck can transport. Most mining trucks range from 50 to 400 tons. An adequate payload ensures efficiency in operations yet can strain the vehicle if overloaded.

Another important aspect is horsepower. A strong engine provides better torque for navigating rough terrains. Look for trucks with robust engines that can handle steep gradients. This feature enhances productivity and lowers downtime. Visibility is also essential. Trucks should have large windows and advanced camera systems. These systems help operators see blind spots and increase safety on-site.

Durability matters as well. Mining trucks should withstand harsh conditions. Look for features like reinforced frames and reliable suspension systems. These details contribute to the truck's longevity. However, not all trucks meet durability expectations. Frequent maintenance might be necessary to keep them running smoothly. Balancing these specifications can be challenging but essential for optimal performance.

Mining trucks play a vital role in the extraction industry. Their design is tailored to handle heavy loads and tough terrains. In recent years, the global market for mining trucks has seen significant growth, estimated at over $27 billion in 2023. This growth is driven by increased demand for minerals and ores.

Common brands offer a variety of models. These trucks vary in size and capacity, from 40-ton to over 400-ton payloads. Popular models often feature advanced technologies like GPS and telematics. However, new entrants struggle to compete against established brands. They often lack the research and development backing that improves safety and efficiency.

Despite technological advances, issues like fuel consumption still arise. Many models consume more fuel than desired. In some reports, up to 30% improvement in efficiency is attainable. Yet, these improvements are often not realized. Users must weigh options carefully. Choosing the right model is only part of the challenge. Maintenance and operational costs also play significant roles in decision-making.

The mining industry is on the brink of a technological revolution. Mining trucks are evolving to meet future demands. Electric and hybrid options are gaining popularity. These trucks can reduce emissions and operational costs. They are quieter and require less maintenance.

Innovation also leads to improved safety features. Autonomous trucks are now a reality. They reduce human error and increase efficiency. However, relying solely on technology raises concerns. The human touch is still essential in operations. Regular training and development are crucial for workers.

Tips: Consider embracing new technologies gradually. Keep an open line of communication with your team. Safety must always be a priority as you adopt new systems. The future of mining trucks looks promising, yet we must be cautious. Balancing innovation with human oversight is key.