In the evolving landscape of mining technology, optimizing the efficiency and performance of ETF Mining Trucks is crucial. Industry expert John Smith, a leading engineer at Mining Solutions Corp, emphasizes, "Every minor improvement in ETF Mining Truck design can lead to massive gains in output." This sentiment reflects the growing need for innovation within the sector.

Efficiency in ETF Mining Trucks plays a significant role in reducing operational costs. It involves meticulous attention to design, maintenance, and training. Small modifications can greatly impact fuel efficiency and payload capacity. However, challenges often arise, such as the trade-offs between speed and durability. These complexities must be acknowledged and addressed.

While new technologies promise enhancements, not every initiative proves successful. Companies must critically assess which strategies truly benefit their operations. Advances in materials and automation are vital, yet implementation can be flawed. Reflecting on past efforts reveals lessons that inform future developments. Continuous improvement in ETF Mining Truck performance is essential for sustainable growth.

ETF mining trucks are designed for heavy-duty operations. Understanding their basic functions is crucial for optimizing performance. These trucks move large quantities of material efficiently. Using advanced technologies improves their productivity and safety. Each truck has various components that significantly impact operations.

Fuel efficiency is often overlooked. Many operators ignore regular maintenance, leading to increased fuel consumption. It's essential to perform routine checks on engines and tires. These small steps can make a big difference in efficiency. Adjusting load weights can also affect performance. An overloaded truck consumes more fuel and risks breakdowns.

Driver training plays a critical role. Skilled operators can manage loads better, enhancing both performance and safety. Despite advancements in technology, human error remains a concern. Continuous training and simulations can help reduce mistakes. Monitoring performance metrics is necessary. Data analysis can identify areas for improvement. This ongoing process can lead to significant enhancements over time.

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Fuel Efficiency | 3.5 | km/l | Average fuel consumption rate. |

| Load Capacity | 45 | tons | Maximum capacity for transport. |

| Average Speed | 15 | km/h | Operational speed under load. |

| Maintenance Interval | 500 | hours | Recommended maintenance schedule. |

| Operator Training | 40 | hours | Total hours of required training. |

Efficiency in ETF mining trucks is crucial for maximizing productivity. Key performance metrics help assess this. Fuel consumption is a primary metric. According to recent industry reports, an average ETF mining truck consumes about 2.5 gallons of fuel per hour. Reducing this by just 15% can lead to substantial savings for operations.

Another vital metric is load capacity. Industry data shows that many trucks often operate at only 75% of their optimal capacity. This underutilization impacts profitability. Regular maintenance also plays a role; trucks that are not properly serviced can lose up to 20% of their efficiency. Monitoring tire wear, for instance, can prevent unnecessary fuel waste.

Finally, tracking is essential. Research indicates that unexpected mechanical failures account for 15% of operational downtime. This can severely hinder performance. Teams must analyze failure patterns to improve reliability. Strategic investment in training and technology may yield better outcomes. Understanding these metrics is a continuous process, and reflection is necessary for improvement.

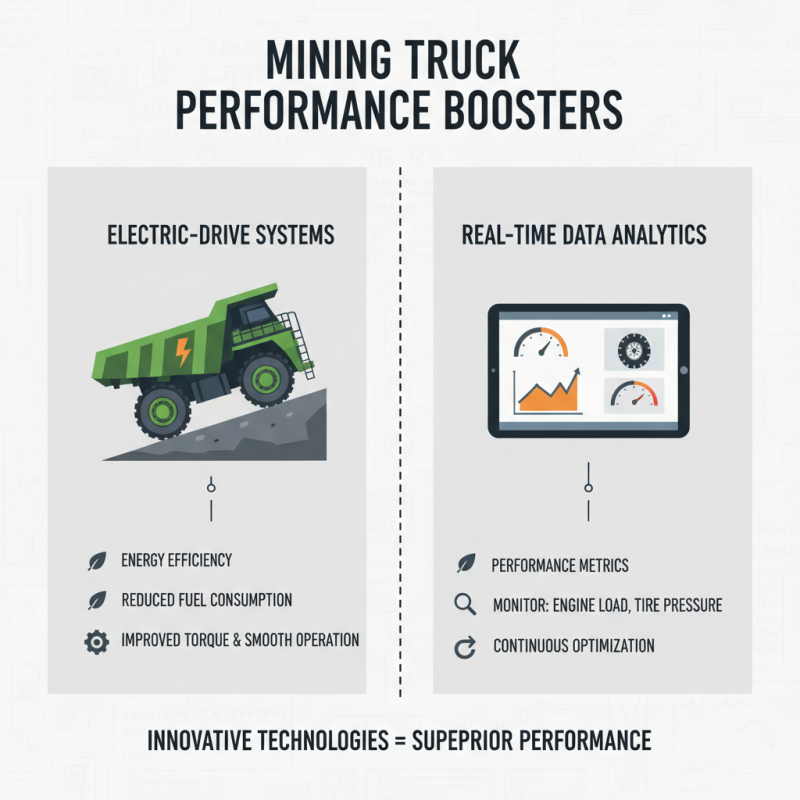

Innovative technologies are crucial in enhancing mining truck performance. Electric-drive systems are revolutionizing energy efficiency. These systems reduce fuel consumption and improve torque delivery. This allows trucks to operate smoothly, even on rough terrain. Real-time data analytics can identify performance metrics. By monitoring engine load and tire pressure, operators optimize performance continuously.

Telematics systems also play a significant role. They track location, speed, and maintenance needs. This information helps operators schedule timely repairs. However, data management can become overwhelming without proper systems in place. Adopting new technologies can create challenges in training staff. The need for ongoing education is vital but often overlooked.

Automation is transforming mining operations as well. Autonomous trucks can work longer hours, reducing labor costs. Yet, the initial investment in this technology can be steep. Companies must weigh the long-term benefits against upfront costs. Addressing these challenges requires strategic planning and a willingness to adapt. Balancing innovation and practicality is key for optimizing efficiency.

Mining equipment requires consistent maintenance to optimize long-term performance. Regular inspections help identify potential issues before they escalate. Keeping an eye on tire conditions is crucial. Worn tires can decrease efficiency and increase fuel costs. Operators should create a routine for tire rotations and pressures.

Lubrication is another key factor. Using the right lubricants can enhance machinery functionality. A proper lubrication schedule reduces wear and tear. It’s essential to keep parts clean. Dust and debris can compromise equipment longevity. Regular cleaning prevents unnecessary breakdowns.

Additionally, training operators is often overlooked. Knowledgeable operators can identify problems early. Empowering them with skills improves safety and efficiency. Mistakes do happen, and learning from them is vital. Regular training sessions can address common issues. A proactive approach can make all the difference in maintaining mining equipment.

Environmental factors significantly influence the efficiency of ETF mining trucks. Weather conditions like rain or snow can impact traction. This affects how quickly trucks can haul materials. High temperatures may cause overheating, reducing performance. Operators need to monitor these conditions closely.

Altitude is another crucial factor. Trucks operating in high elevations can experience engine strain. The thinner air reduces engine efficiency. It’s important for operators to adjust their strategies accordingly. They might need to change routes or schedule maintenance more frequently.

Fuel quality also plays a role. Poor fuel can lead to inefficient combustion. This results in lower power output and higher emissions. Regular checks on fuel quality can help mitigate this issue. Adjusting operational practices based on environmental conditions can optimize overall performance. Every small detail contributes to better efficiency and productivity.

This chart demonstrates the impact of various environmental factors on ETF mining truck efficiency. The data reflects the percentage influence of elements such as temperature, altitude, humidity, and soil density on the overall performance of mining trucks in 2026.