In the world of mining, the efficiency of operations hinges on effective management of resources. Mining Rock Trucks play a vital role in this industry. These heavy vehicles are not just transportation tools; they are pivotal in moving materials swiftly and safely. According to John Smith, a leading expert in mining logistics, "Optimizing the use of Mining Rock Trucks can significantly boost productivity."

However, operating these trucks is not without its challenges. Mismanagement can lead to costly downtime and even accidents. It is crucial to pay attention to both maintenance and operational efficiency. Small issues, if overlooked, can escalate and disrupt the entire workflow. Regular inspections and proper training make a difference.

Understanding the nuances of Mining Rock Truck operation and upkeep is essential. It's about striking a balance between productivity and safety. Every mine has unique demands that require tailored approaches. Learning from past mistakes can foster more effective practices. Investing in this knowledge ensures smoother operations and longer vehicle life.

Mining rock trucks are essential in the extraction process. They transport materials from the mining site to processing areas. Understanding their operation is key for optimizing productivity. These trucks have large capacities and can move significant amounts of ore. However, efficiency can sometimes take a backseat to speed. Operators need to focus on route selection and load distribution.

Proper maintenance is crucial for safe operations. Regular inspections help identify issues before they become costly. Neglecting routine checks can lead to failures that might halt operations. Inexperienced operators may struggle with these heavy vehicles. Training is necessary but often overlooked. A well-trained operator can improve fuel efficiency and reduce wear on the truck.

Environmental factors affect operations too. Muddy surfaces can slow down transport times. Optimizing routes through different terrains requires foresight. Adjusting driving techniques based on weather can save time and resources. All these aspects combine to create a more efficient mining process. But, there’s always room for improvement. Continuous feedback from operators is essential for refining practices.

When selecting a rock truck for mining, several key features demand attention. Firstly, payload capacity is critical. A truck that carries a high payload can improve efficiency. According to the Mining Equipment Industry report, the most effective models can handle up to 100 tons per trip. This efficiency reduces operational costs over time.

Another important aspect is maneuverability. Trucks need to navigate tight spaces and rough terrain. It’s essential to choose a truck designed for stability and ease of movement. Look for features like articulated steering. This can enhance operational safety and control.

Tips for efficient operation include regular maintenance checks. Monitor tire pressure and engine performance for optimal function. Ensure the truck is not overloaded to avoid unnecessary wear. Keep an eye on the loading frequency; striking a balance is vital to maintain productivity without stressing the machine. Reflect on driving practices as well. Training operators can lead to smoother operation and reduced fuel consumption. With the right features and practices in place, rock trucks can significantly boost productivity in mining operations.

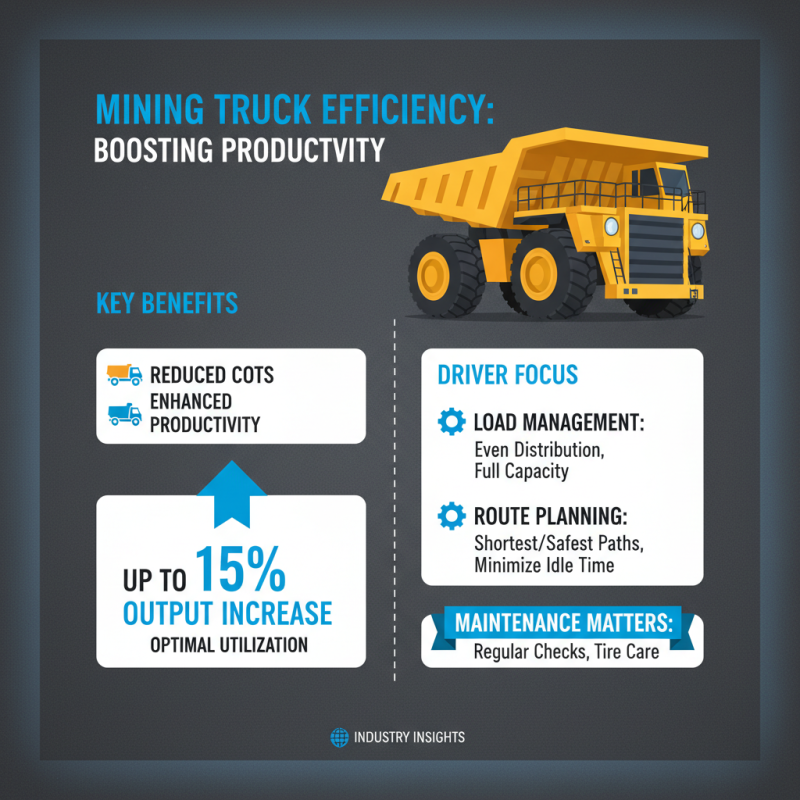

Mining rock trucks play a vital role in the efficiency of mining operations. Proper operation and maintenance can significantly reduce costs and enhance productivity. According to industry reports, optimal truck utilization can lead to a 15% increase in output. To achieve this, drivers should focus on load management and route planning.

Tips for efficient operation include maintaining a uniform load distribution. Uneven loads can lead to equipment wear. Overloading a truck may cause mechanical failures, which can halt operations. Regular inspections are necessary. Daily checks on tire pressure and brake systems can prevent accidents.

Furthermore, training operators is crucial. Knowing how to handle the truck in various terrains saves fuel and minimizes wear. Data from industry studies indicate that skilled operators can lower fuel consumption by up to 10%. Implementing a routine maintenance schedule is equally important, yet often overlooked. Trucks that receive consistent maintenance show noticeably improved performance. Operators should reflect on their daily practices. Unconscious habits may lead to inefficiencies. Assessing these can enhance overall operation and save on maintenance costs.

Effective maintenance of mining rock trucks significantly impacts their longevity and performance. Regular inspections are crucial. Data indicates that timely maintenance can improve equipment lifespan by up to 30%. Operators should establish a routine that includes checks on tire pressure, brakes, and hydraulic systems. Neglected components can lead to severe malfunctions, which can halt operations unexpectedly.

The importance of proper lubrication cannot be overstated. Many operators overlook this aspect, which can lead to premature wear. According to industry reports, appropriate lubrication can reduce wear and extend component life by 20%. Ensuring that all moving parts are adequately greased helps in maintaining smooth operations. Failure to do so may result in costly repairs and downtime.

Training operators on best practices is essential. A well-trained operator can spot potential issues before they escalate. It’s common for less experienced personnel to miss small signs of trouble. Regular training sessions can keep everyone alert. A focus on maintenance culture could yield significant gains in efficiency and productivity.

Operating rock trucks in mining environments poses unique challenges. Safety is of utmost importance. According to the Mine Safety and Health Administration (MSHA), approximately 40% of mining injuries are related to vehicle operation. These incidents often involve transport vehicles like rock trucks, which are large and heavy. Operators must be trained and vigilant to prevent accidents, particularly in confined spaces.

One critical safety consideration is visibility. Operators should ensure that all mirrors and cameras are functioning. Blind spots can lead to collisions, especially in busy areas. Additionally, maintaining a safe distance from other equipment is essential. A report by the National Institute for Occupational Safety and Health (NIOSH) indicates that improving spatial awareness can reduce accidents significantly.

Regular maintenance checks are also vital. Neglected trucks can develop mechanical issues that compromise safety. Operators should perform daily inspections before use, focusing on brakes and tires. A study from the American Society of Mining and Reclamation found that 15% of accidents were linked to equipment failure. This highlights the need for rigorous operational protocols to foster a safer workplace.

| Tip | Description | Safety Considerations | Maintenance Frequency |

|---|---|---|---|

| Regular Inspections | Conduct daily inspections to identify hardware issues early. | Use personal protective equipment (PPE) during inspections. | Daily |

| Load Limits | Adhere to maximum load limits to prevent tipping and damage. | Be aware of load stability and center of gravity. | Every load |

| Proper Training | Ensure operators are trained on equipment use and safety protocols. | Conduct regular safety drills. | Annually |

| Hydraulic System Checks | Regularly check hydraulic hoses and connections for leaks. | Use caution with high-pressure systems. | Weekly |

| Tire Maintenance | Check tire pressure and tread regularly to prevent blowouts. | Inspect for foreign objects that could cause punctures. | Monthly |