The Mining Rock Truck is a crucial piece of equipment in the mining industry. These massive vehicles transport ores and minerals from mining sites to processing areas. According to expert David Hargrove, "Mining Rock Trucks are the backbone of efficient mineral transportation." Their robust design allows them to handle heavy loads on rough terrains.

These trucks come in various sizes, each suited for different types of mining operations. A large Mining Rock Truck can haul tons of material with ease. However, challenges persist. Operators must navigate steep inclines and avoid obstacles, making skill essential.

While Mining Rock Trucks improve productivity, maintenance is often overlooked. A well-maintained truck ensures safety and efficiency, yet many sites face issues with equipment neglect. As the industry evolves, it’s vital to reflect on how to optimize the use of these trucks. Embracing technology could lead to better performance and safety standards in the future.

Mining rock trucks are specialized vehicles designed for transporting heavy loads in mines. They are essential for moving materials like ore and waste rock. Various types exist, each with unique features and specifications. These trucks come in different sizes, which affects their capacity and maneuverability.

One common type is the articulated dump truck. It features a hinge between the front and rear. This design allows better control on rough terrains. Another popular option is the rigid dump truck. It offers more stability and larger payloads. However, its size can hinder movement in tight spots. Operators must choose wisely based on their specific mining needs.

Some trucks boast eco-friendly engines. These are gaining traction due to increasing environmental concerns. Other models prioritize payload capacity over fuel efficiency. This can lead to higher costs in the long run. Every choice carries its own benefits and drawbacks. It's crucial for mining companies to weigh these factors carefully.

Mining rock trucks are essential for transporting materials in mining operations. These trucks are designed to handle heavy loads and rough terrains. Their robust structure ensures durability against challenging conditions. A key component of these trucks is the dump bed, which tilts to unload materials efficiently. Operators can quickly dump loads, improving productivity on site.

Another important feature is the chassis. The chassis supports the entire truck and houses critical systems. It must be strong to withstand the weight and stress from heavy loads. Additionally, the drivetrain is vital for power and traction. It helps the truck navigate steep gradients and uneven surfaces. However, these systems require regular maintenance to prevent breakdowns.

The engine also plays a crucial role in performance. Powerful engines provide the necessary horsepower for operation. However, they can be fuel-inefficient if mismanaged. Operators must monitor fuel usage closely to optimize performance. Small changes, like refueling at optimal times, can make a difference. Frequent checks and inspections can help prolong the last life of mining rock trucks.

Mining rock trucks play a crucial role in transporting materials from extraction sites.

These trucks are enormous, designed to handle heavy loads of mined resources. Typically, they have large dump beds that can carry multiple tons of rock.

The massive size allows them to navigate rough terrains, often found in mining sites.

These trucks are powered by diesel engines.

The engines generate significant horsepower, enabling the trucks to haul heavy loads.

The operation relies on hydraulic systems that lift and dump material efficiently. Operators must be skilled, as maneuvering in tight or uneven spaces can be challenging.

Safety is essential, but accidents do happen. Operators sometimes make mistakes under pressure,

highlighting the need for continuous training.

Despite advancements in technology, some older designs remain in use.

Upgrades can be costly, and not all sites prioritize them. This can impact efficiency and safety measures.

Understanding these trucks' operating systems is vital but often overlooked. Making improvements requires ongoing reflection and adaptation in the

mining industry, as technology and methods evolve.

Mining rock trucks are crucial in the industry, yet safety features often get overlooked. Operators face numerous hazards daily. According to industry reports, about 50% of mining accidents involve vehicles. Therefore, ensuring safety in rock trucks is vital.

Modern mining rock trucks incorporate several safety features. For instance, many trucks include advanced braking systems. This technology can reduce stopping distances by up to 30%. Visibility is another important factor. Many trucks come equipped with rearview cameras and sensors. These help operators avoid collisions while maneuvering in tight spaces. However, despite these advancements, incidents still occur. Proper training and consistent maintenance remain significant challenges.

Despite improved features, human error is still a threat. Over 70% of mining accidents involve operator mistakes. This indicates a need for ongoing training and safety protocol reinforcement. Operators must understand the capabilities and limitations of their trucks. Additionally, regular safety audits can help identify potential issues. Companies should prioritize these audits to enhance overall safety. It’s essential to reflect on past incidents to prevent future ones.

| Feature | Description | Importance |

|---|---|---|

| Payload Capacity | Typically ranges from 40 to 400 tons. | Allows for efficient transport of materials from mine sites. |

| Dumping Mechanism | Hydraulic systems that raise the truck bed for unloading. | Reduces time and labor costs during operation. |

| Safety Features | Includes roll-over protection, emergency brakes, and seat belts. | Enhances operator safety and reduces accident risks. |

| Engine Types | Diesel engines with high torque ratings. | Enables trucks to operate under heavy load conditions. |

| Tire Size | Usually between 25 to 51 inches in diameter. | Improves traction and stability on rough terrain. |

| Maintenance Requirements | Regular inspections and component replacements. | Ensures longevity and reliability of the truck. |

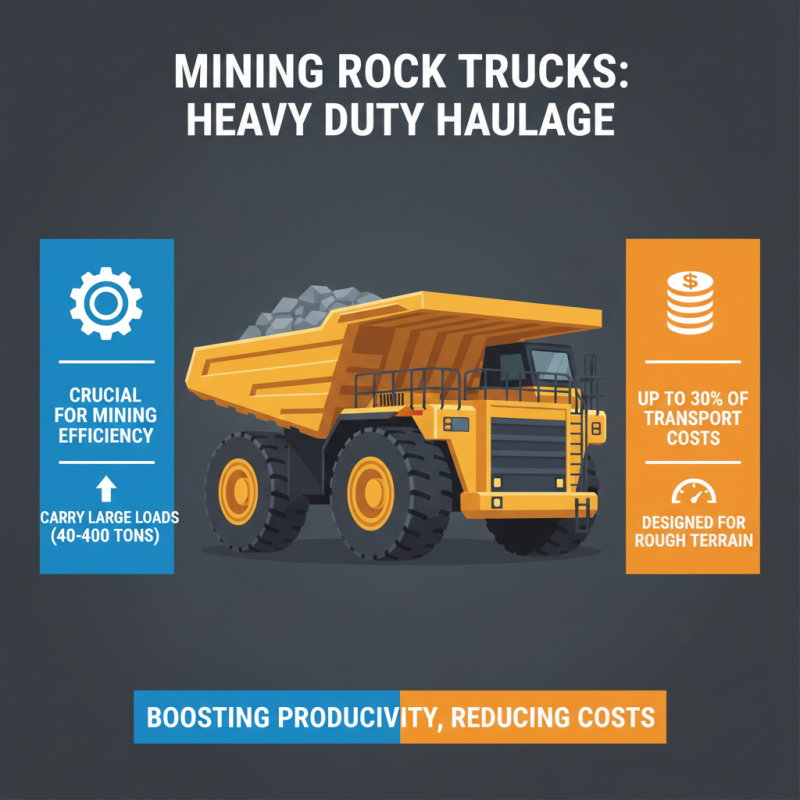

Mining rock trucks play a crucial role in the mining industry. They are designed for heavy-duty operations. These trucks can carry large loads over rough terrains. Typically, they have capacities ranging from 40 to 400 tons. Reports indicate that these trucks contribute significantly to operational efficiency. In fact, they account for up to 30% of total transportation costs in some mining operations.

The applications of mining rock trucks are diverse. They are essential in the extraction phase. These trucks transport materials like ore and waste from mines to processing plants. According to industry data, their efficiency can reduce turnaround times by 20%. This makes them vital in maintaining production schedules. However, the reliance on these trucks raises concerns. Maintenance costs can be high. Additionally, the environmental impact of running large fleets needs evaluation.

Innovations are underway to improve efficiency. Electric and hybrid models are being explored. These aim to reduce fuel consumption and emissions. Yet, adaptation in existing operations remains a challenge. Training operators on new technologies takes time. It's essential to balance advancements with their practical application in the mining environment.