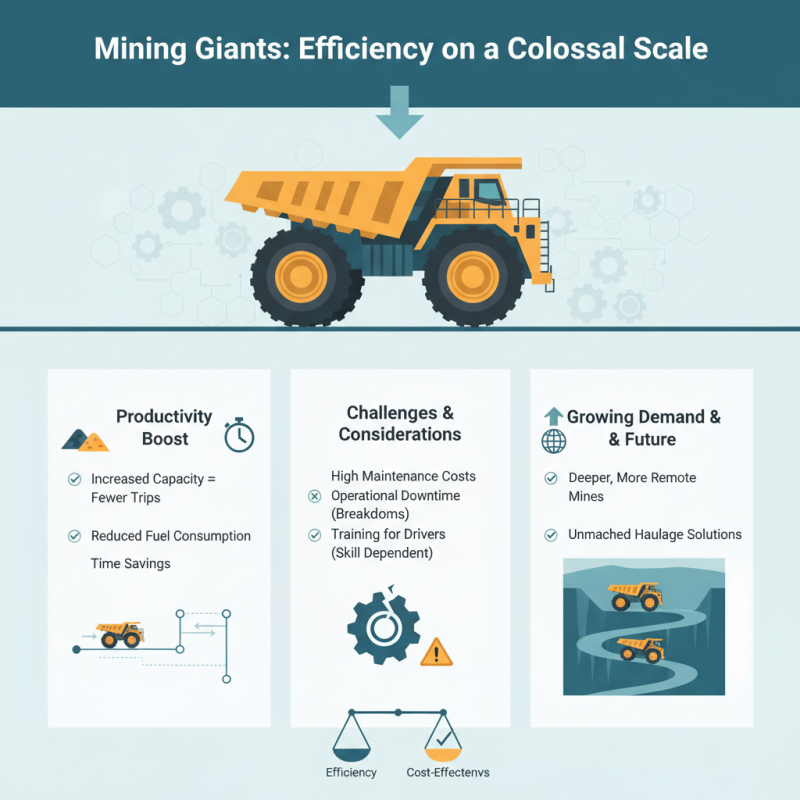

In the mining industry, "Massive Mining Trucks" play a crucial role in enhancing operational efficiency. According to Dr. Emily Carter, an expert in heavy machinery, "These trucks are not just large; they are integral to productivity." Their size and capacity allow them to transport more materials, reducing the number of trips needed to move resources. This not only saves time but also minimizes fuel consumption.

However, relying on these colossal vehicles comes with challenges. Maintenance costs can be significant, and breakdowns can halt operations. Mines must carefully evaluate their use of "Massive Mining Trucks" to ensure they balance efficiency with cost-effectiveness. Ensuring drivers are well-trained is also key. A poorly operated truck can negate its benefits, leading to inefficiencies rather than improvements.

Despite these issues, the demand for "Massive Mining Trucks" continues to grow. As extraction sites become deeper and more remote, these trucks offer solutions that smaller vehicles cannot provide. Yet, companies must reflect on their operations, ensuring that the advantages of using these machines outweigh the potential downsides.

Massive mining trucks play a crucial role in the mining industry. They are designed to transport large volumes of materials. These trucks can carry several hundred tons in a single load. Their ability to navigate rough terrains is essential for mining operations. The efficiency they bring can significantly reduce operational costs.

However, these trucks also come with challenges. Their size often leads to high fuel consumption. Maintenance can be costly and time-consuming. Operators must ensure that these trucks are not only efficient but also safe. The training for drivers is extensive but necessary. Mistakes can result in accidents that delay projects and increase expenses.

The impact of massive trucks extends beyond the immediate site. Their use can reshape how mining companies approach logistics. A well-planned operation can improve production rates. But it requires constant evaluation and adjustment. This reflection is vital for long-term success in the mining industry.

| Parameter | Value |

|---|---|

| Truck Capacity | 400 tons |

| Average Payload | 100 tons |

| Fuel Efficiency | 15 liters/100 km |

| Maximum Speed | 50 km/h |

| Operating Weight | 600 tons |

| Maintenance Cost per Year | $300,000 |

| Average Lifespan | 15 years |

Massive mining trucks have become indispensable in modern mining operations. They greatly enhance efficiency compared to traditional equipment. Data from industry reports show that these trucks can carry loads upwards of 400 tons. This capability allows for fewer trips and reduced operational costs. The sheer size leads to less wear on the infrastructure. However, higher fuel consumption can be an issue.

In contrast, traditional mining equipment often lacks the same carrying capacity. This necessitates more vehicles for hauling, increasing labor and maintenance costs. According to a report by the International Council on Mining and Metals, using larger trucks can reduce the number of vehicles needed by 30%. However, not all operations are suited for such large machinery. Some mining sites might struggle with the size of these trucks, affecting maneuverability.

Investing in massive trucks poses challenges too. They can require extensive training for operators. Additionally, the initial investment is significant. While the efficiency gains can be enticing, poor planning may lead to underutilized assets. Each operation must weigh these factors carefully to ensure that they are making the best decision for their specific needs.

Massive mining trucks play a crucial role in the efficiency of mining operations. Their design directly impacts productivity and cost-effectiveness. These trucks are often equipped with larger payload capacities. This allows them to transport more materials in each trip. As a result, fewer trips are needed, which can decrease fuel consumption.

A key aspect of truck design is the balance between size and maneuverability. Too large, and they struggle on uneven terrain. Yet, if they're too small, they can't handle the load efficiently. The tires and suspension systems must work together to provide stability. When poorly designed, trucks can lead to delays and increased wear.

Moreover, technology integration is vital. Features like automatic braking and load monitoring can enhance safety and performance. However, not all trucks have these advancements. This can lead to inefficiencies and higher operational costs. Operators must evaluate their fleet regularly to ensure optimal design and performance.

Massive mining trucks play a critical role in the extraction process. However, their environmental impact raises concerns. These trucks consume significant fuel, leading to high carbon emissions. They can disturb local ecosystems and wildlife habitats as well. Mining operations need to evaluate this effect carefully.

Tips: Consider alternative fuels for these trucks. Electric options may reduce emissions. Regular maintenance can also enhance fuel efficiency.

Heavy mining trucks generate noise and dust, impacting nearby communities. This can lead to health problems for residents. Implementing noise barriers and dust suppression techniques is essential. Collaboration with local communities can foster trust and ensure better environmental stewardship.

Tips: Engage local leaders in discussions. Their input can provide valuable insights. Establishing clear communication reduces misunderstandings and builds positive relationships.

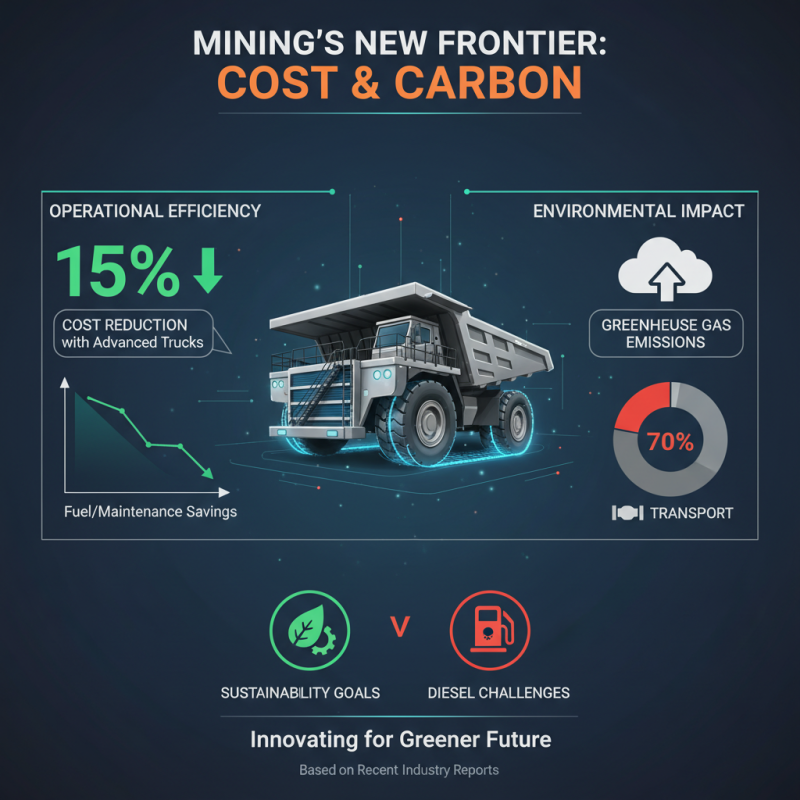

The mining industry is evolving rapidly, especially with advancements in technology and sustainability. Recent reports indicate that massive mining trucks can reduce operational costs by up to 15%. These trucks play a critical role in transporting minerals efficiently. However, they also pose environmental challenges. Diesel-powered trucks emit significant greenhouse gases. Approximately 70% of their emissions are from transportation. This raises questions about long-term viability.

Emerging trends focus on electric and hybrid truck technologies. Research suggests that electric trucks can reduce emissions by 80%. This is a significant improvement, but infrastructure remains a barrier. Charging stations in remote mining locations are scarce. Also, battery production raises ethical and environmental concerns. The mining sector must balance efficiency with sustainability and social responsibility.

Investing in innovative solutions like automation is essential. Automated trucks can operate longer hours and minimize human error. However, reliance on technology brings its own risks. Job displacement is a critical issue. While technology is key to future sustainability, careful consideration is needed to address its challenges. Balancing efficiency with environmental and social impacts remains a complex task.