As the mining industry grapples with the challenges of increased efficiency and safety, the advent of Autonomous Mining Trucks is set to revolutionize the sector. According to a recent report by Grand View Research, the global autonomous truck market in mining is projected to reach $3.83 billion by 2025, driven by the need for reducing operational costs and the persistent demand for productivity enhancements. Autonomous Mining Trucks offer solutions to mitigate hazards that human drivers face, improve logistics, and optimize resource extraction.

Industry expert Dr. Emily Smith, a prominent figure in autonomous vehicle technology, notes, “The implementation of Autonomous Mining Trucks not only transforms the way resources are extracted but also significantly enhances safety standards in remote and hazardous environments.” As companies increasingly adopt this technology, they are finding that these trucks can operate continuously and with precision, leading to increased throughput and reduced downtime.

With the integration of advanced sensors, AI, and machine learning, Autonomous Mining Trucks are poised to become an indispensable asset in the mining landscape. This shift not only represents technological advancement but also signifies a paradigm change in workforce management, operational protocols, and environmental sustainability in the mining industry. The future is indeed promising for those willing to embrace this innovation.

The evolution of autonomous mining trucks has significantly transformed the mining sector, enhancing operational efficiency and safety. Initially conceptualized in the late 20th century, these trucks went through a gradual transition from being human-operated to incorporating advanced automation technologies. Early models relied heavily on operator input and were limited to basic navigational assistance. However, advancements in sensor technology, GPS, and artificial intelligence paved the way for the creation of fully autonomous vehicles capable of navigating complex terrains and coordinating seamlessly with other machinery.

As the mining industry continues to adopt these autonomous solutions, the benefits become increasingly apparent. The integration of sophisticated algorithms enables trucks to optimize routes in real-time, leading to reduced fuel consumption and operational costs. Furthermore, by minimizing human involvement in potentially hazardous environments, companies can enhance worker safety and reduce the risk of accidents. The ongoing development of these technologies promises not only to streamline mining processes but also to contribute to sustainable practices within the industry, minimizing environmental impact while maximizing productivity.

| Metric | 2023 Estimate | 2025 Projection | 2030 Projection |

|---|---|---|---|

| Number of Autonomous Trucks | 150 | 300 | 600 |

| Operational Efficiency Improvement (%) | 15% | 25% | 40% |

| Reduction in Operating Costs (%) | 10% | 20% | 35% |

| Percentage of Mines Using Autonomous Trucks (%) | 5% | 15% | 30% |

| Safety Improvement (%) | 20% | 30% | 50% |

The development of autonomous mining trucks is significantly influenced by several key technologies that enhance their operational efficiency and safety. One of the primary technologies driving this transformation is advanced sensor systems. These sensors enable trucks to gather real-time data about their surroundings, including potential obstacles, terrain variations, and other vehicles. By utilizing LiDAR, radar, and camera systems, these trucks can navigate complex mining environments autonomously, reducing the likelihood of accidents and downtime.

Another crucial technology is artificial intelligence (AI), which powers the decision-making processes of autonomous mining trucks. AI algorithms analyze data from the sensor systems to optimize routing, improve load management, and adapt to changing site conditions. Machine learning techniques allow these systems to continuously improve their performance, learning from previous operations to enhance efficiency and reduce fuel consumption. Moreover, connectivity technologies such as 5G enable seamless communication between trucks and central control systems, allowing for coordinated operations and real-time monitoring.

Together, these technologies are laying the groundwork for a future where autonomous mining trucks can operate independently, contributing to increased productivity and reduced operational costs in the mining industry. As these innovations continue to develop, they promise to reshape the landscape of mining operations, fostering a safer and more efficient working environment.

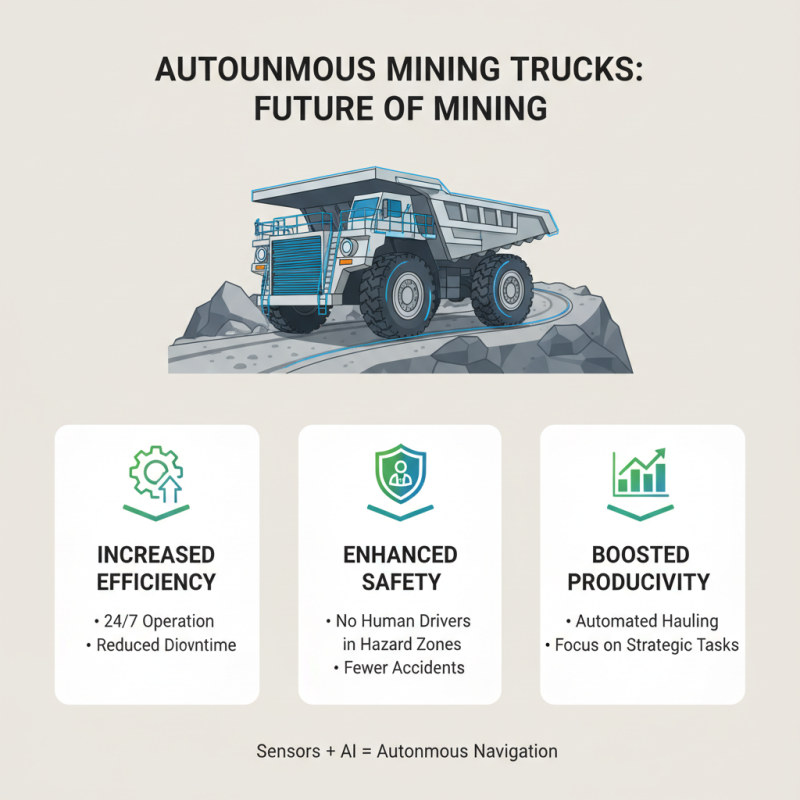

The introduction of autonomous mining trucks represents a significant advancement in the mining industry, particularly in terms of efficiency and productivity. These self-driving vehicles are designed to operate without human intervention, using advanced sensors and artificial intelligence to navigate complex terrains. By automating the hauling process, mining operations can experience reduced operational downtime and enhanced safety conditions, allowing human workers to focus on more strategic tasks rather than routine driving.

Moreover, autonomous trucks are capable of optimizing routes and schedules dynamically, leading to increased load management and resource utilization. This capability significantly decreases the time trucks spend idle, resulting in faster turnaround times and higher throughput. As these trucks work around the clock without the need for breaks, the overall productivity of mining operations is substantially improved. Additionally, the accuracy of data collected by autonomous systems enables better planning and decision-making, further elevating efficiency levels within the industry.

The integration of autonomous mining trucks is anticipated to revolutionize safety standards within the mining industry. According to a report by the International Council on Mining and Metals, accidents in mines have decreased by over 30% due to the implementation of automation technologies. Autonomous trucks eliminate many of the human factors that contribute to accidents, such as fatigue and poor decision-making during high-stress situations. By utilizing advanced sensors and AI-driven navigation systems, these vehicles can operate more safely in hazardous environments, significantly reducing the risk of collisions and human injuries.

However, the deployment of autonomous mining vehicles raises important regulatory considerations. The mining sector must establish clear guidelines to mitigate the risks associated with new technologies. A study by the National Institute for Occupational Safety and Health emphasizes the need for robust regulatory frameworks that address not only the operation of autonomous equipment but also workforce training and emergency response procedures. As companies strive to comply with these regulations, ongoing dialogue among industry stakeholders, regulators, and technology developers will be crucial in shaping a safe and efficient future for mining operations.

The autonomous mining truck market is witnessing significant evolution, driven by advancements in technology and a growing emphasis on operational efficiency. The integration of artificial intelligence and machine learning is enabling these trucks to navigate complex mining environments with enhanced precision, minimizing human error and maximizing productivity. As companies aim to reduce operational costs and improve safety, autonomous vehicles are becoming a game-changer in the mining industry.

Market projections suggest that the future of autonomous mining trucks will see increasing adoption rates, particularly in regions with large-scale mining operations. Enhanced data analytics capabilities are expected to optimize logistics and equipment management, while advancements in battery technology will improve the sustainability of these vehicles. The push towards automation is not just a trend but a strategic shift, as mining companies invest in innovation to meet the demands of a more competitive landscape, while also aligning with global sustainability goals.