Operating a Giant Mining Truck effectively is crucial for maximizing productivity and ensuring the safety of all personnel involved in mining operations. These colossal machines play a pivotal role in transporting minerals and materials from the quarry to processing sites, making their efficient operation essential for the overall success of mining projects. As the mining industry evolves, so does the technology and techniques related to handling such massive vehicles.

In this article, we present the top 10 tips for operating a Giant Mining Truck with the utmost efficiency. By focusing on key operational guidelines, drivers and operators can enhance their skills and adopt best practices that lead to smoother operations. From understanding the vehicle's nuances to implementing safety protocols, these tips are designed to help professionals in the field navigate the complexities of giant mining operations. As we delve deeper into each tip, it will become evident how proper training, communication, and adherence to safety measures can significantly impact both the effectiveness and safety of operating a Giant Mining Truck.

Giant mining trucks are a cornerstone of modern mining operations, designed to transport vast quantities of materials efficiently. These trucks typically feature a payload capacity that can exceed 400 tons, significantly enhancing productivity on mining sites. The key specifications of such vehicles include powerful engines, often exceeding 3,000 horsepower, which enable them to haul heavy loads on rugged terrain. Additionally, the usage of advanced hydraulics and automated systems improves their operation, allowing for precise control and reduced downtime. According to the International Council on Mining and Metals (ICMM), optimizing the performance of giant mining trucks can lead to increased operational efficiency by up to 30%, underscoring the importance of understanding their features.

Furthermore, giant mining trucks are equipped with state-of-the-art technologies such as GPS tracking and telemetry systems, which facilitate real-time data monitoring and analysis. This capability enables operators to optimize routes, monitor fuel consumption, and reduce maintenance costs. Reports indicate that implementing such technologies can yield a reduction in operational costs by as much as 15%. Moreover, safety features including advanced braking systems and stability controls are critical, as they enhance the safety of operators and personnel working in proximity to these massive machines. By comprehending the intricate specifications and features of giant mining trucks, operators can ensure not only improved efficiency but also heightened safety on the worksite.

This chart presents key specifications of giant mining trucks, including their load capacity, fuel efficiency, maximum speed, service intervals, and turning radius. These factors are crucial for effective operation in mining environments.

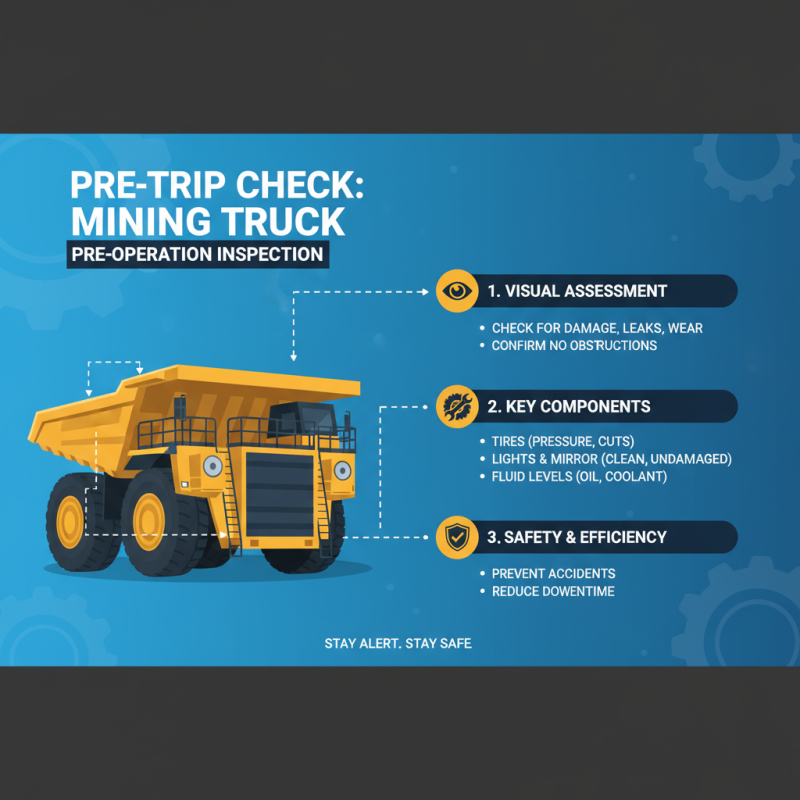

Before operating a giant mining truck, conducting thorough pre-operation inspections is crucial for ensuring safety and efficiency. These inspections should begin with a visual assessment of the vehicle's exterior. Operators must check for any visible damage, leaks, or wear that might affect the vehicle’s performance. Components like tires, lights, and mirrors must be carefully inspected to confirm they are in good condition. Attention to detail during this phase can prevent accidents and costly downtime.

In addition to the external checks, internal systems such as the braking, steering, and hydraulic systems require operational testing. Operators should ensure that all gauges and warning lights function properly. A key part of this process is verifying fluid levels, including oil, coolant, and transmission fluid, which are essential for maintaining the truck's performance. Routine pre-operation inspections not only enhance safety but also improve the truck's operational lifespan, ensuring that it runs efficiently during shifts. By adhering to these critical inspection steps, operators can foster a safer working environment and maximize productivity on the mining site.

Effective fuel management is crucial for optimizing the operational costs of giant mining trucks, which are known for their significant fuel consumption. According to the International Council on Mining and Metals (ICMM), heavy-duty trucks in the mining sector can consume as much as 300 liters of diesel per hour under full load conditions. This high fuel demand underscores the need for best practices in fuel management to improve efficiency and reduce environmental impact.

Implementing a robust fuel monitoring system can have a significant effect on cost reduction. Data from a recent report by the Mining Industry Council indicates that mines that utilize advanced fuel tracking and monitoring technologies can reduce fuel consumption by up to 15%. By closely tracking fuel usage, operators can identify inefficiencies, such as excessive idling or unnecessary load hauling, thus proactively addressing these issues to cut down on wasteful spending.

Furthermore, regular maintenance of trucks contributes to better fuel efficiency. A study by the Society for Mining, Metallurgy & Exploration (SME) revealed that well-maintained equipment could improve fuel consumption by roughly 10%. Keeping trucks in optimal working condition ensures they operate at peak efficiency, leading to considerable savings in fuel costs over time. Adopting scheduled maintenance programs and investing in high-quality fuel can further enhance performance and economic viability in mining operations.

| Tip No. | Tip Description | Expected Fuel Savings (%) | Operating Cost Impact ($) |

|---|---|---|---|

| 1 | Regular Maintenance Checks | 10% | $2,000 |

| 2 | Optimize Load Distribution | 8% | $1,600 |

| 3 | Implement Fuel Monitoring Systems | 12% | $2,400 |

| 4 | Train Operators on Best Practices | 15% | $3,000 |

| 5 | Reduce Idle Time | 20% | $4,000 |

| 6 | Use Quality Fuel | 5% | $1,000 |

| 7 | Adopt Efficient Route Planning | 18% | $3,600 |

| 8 | Monitor Tire Pressure Regularly | 9% | $1,800 |

| 9 | Implement Telemetry Systems | 14% | $2,800 |

| 10 | Review Fuel Management Policies | 11% | $2,200 |

Maneuvering giant mining trucks in challenging terrain requires a blend of skill, awareness, and tactical decision-making. Understanding the terrain is crucial; operators should familiarize themselves with the specific landscape where they will be driving. This includes assessing slopes, potential obstacles, and areas prone to mud or loose gravel. A careful inspection of the route can help operators identify and prepare for potential hazards, ensuring a smoother operation.

Moreover, effective speed management is essential when navigating rough terrain. Operators should adjust their speed based on the conditions—slowing down on incline changes, rocky paths, or narrow passages. This not only enhances the control over the vehicle but also ensures better stability, reducing the risk of accidents. Employing techniques such as using the truck’s low gear can significantly improve traction, especially on steep or slippery surfaces. Adequate communication with ground personnel also plays a vital role, providing additional awareness of the surrounding environment and the presence of other machinery, which aids in executing safe maneuvers.

Analyzing operational data is crucial for enhancing the performance metrics of giant mining trucks, which are a backbone of the mining industry. According to a 2022 report by the International Council on Mining and Metals, operational efficiency in mining operations can be significantly improved by utilizing data analytics to assess vehicle performance, maintenance needs, and load factors. For instance, leveraging telemetry systems allows operators to gather real-time data on fuel consumption, tire wear, and payload capacity, enabling proactive adjustments that optimize operational efficiency.

Furthermore, insights drawn from historical performance data can inform scheduled maintenance and operational adjustments that decrease downtime. A recent study indicated that mines utilizing predictive maintenance practices can achieve a 30% reduction in truck repair costs and enhance overall fleet availability by 25%. By closely monitoring performance metrics such as cycle times and load efficiency, operators can implement strategic changes that not only enhance productivity but also contribute to sustainability goals by reducing fuel consumption and minimizing emissions. Therefore, analyzing operational data becomes indispensable in driving better performance outcomes in giant mining truck operations.