In the mining industry, the "Coal Mine Haul Truck" plays a pivotal role in transporting coal from extraction sites to processing plants. These massive vehicles are specifically designed to handle the arduous conditions of mining environments, boasting capacity ratings that can exceed 400 tons per load. According to a report by the International Mining Association, efficient haulage systems, including the use of haul trucks, account for about 50% of the total operational costs in coal mining operations. This highlights the critical nature of effective transport solutions in maximizing productivity and reducing expenses.

Industry expert Dr. Emily Roberts, a leading authority on mining logistics, emphasizes the importance of innovation in haul truck technology. She states, “The evolution of the Coal Mine Haul Truck has transformed the efficiency and safety of coal transportation, allowing miners to transport larger quantities with less energy consumption.” As the demand for coal remains, understanding the operational dynamics of these haul trucks becomes essential for industry stakeholders aiming to optimize their operations while adhering to sustainable practices. The integration of advanced technologies, such as automation and telematics, is set to further enhance the functionality of these trucks in the near future, ensuring that coal mining continues to evolve in response to global energy needs.

Coal mine haul trucks are indispensable vehicles in the mining industry, specifically designed to transport large quantities of coal from the extraction site to processing areas or loading stations. These trucks are engineered to handle extreme conditions, featuring robust frames and powerful engines capable of navigating rough terrains. According to the World Coal Association, a single large haul truck can carry loads in excess of 300 tons, which significantly enhances the efficiency of coal transportation in mining operations.

The primary purpose of a coal mine haul truck is to streamline the movement of mined coal, thus minimizing downtime and maximizing productivity. Modern haul trucks are equipped with advanced technologies, such as GPS tracking and load sensing systems, which optimize load management and fuel efficiency. The International Council on Mining and Metals (ICMM) highlights that improved logistical operations using haul trucks can reduce transportation costs by up to 10%, underscoring their role in boosting overall operational efficiency in coal mining. Furthermore, with the increasing push for sustainable practices, many companies are focusing on upgrading their fleets to include more energy-efficient and environmentally friendly haul trucks, which aligns with industry goals for reduced carbon footprints.

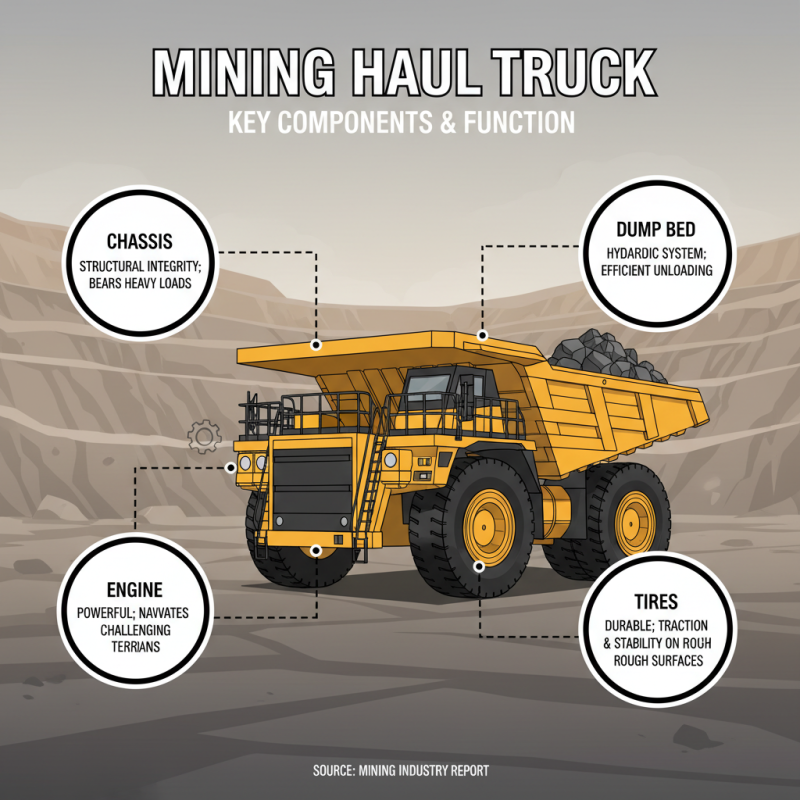

Haul trucks are essential vehicles in the mining industry, specifically designed to transport large volumes of ore and coal from mines to processing plants. The key components of a haul truck include the chassis, engine, dump bed, and tires. The robust chassis provides the structural integrity needed to bear heavy loads, while the powerful engine ensures the truck can navigate challenging terrains. The dump bed, typically equipped with a hydraulic system, allows for efficient unloading of materials. The large, durable tires are designed to withstand rough surfaces and heavy loads, providing traction and stability critical for operating in mining environments.

When considering the design and functionality of a haul truck, one must also take into account the advanced technologies integrated into modern models. Features such as GPS tracking, load monitoring systems, and automated controls enhance efficiency and safety during operations. These innovations assist in minimizing operational costs and improving productivity.

Tips: Always ensure that regular maintenance is performed on haul trucks to prevent breakdowns. Proper training for operators is crucial to the safe handling of these large vehicles. Additionally, implementing a thorough inspection routine can help identify potential issues before they become significant problems, ensuring smoother operations in the mining process.

Coal mine haul trucks play a crucial role in the efficiency of coal transportation within the mining industry. These massive vehicles are specifically designed to carry large volumes of coal from the mining site to processing areas or loading docks. By utilizing advanced engineering, haul trucks optimize the delivery process, reducing the time and labor required for transportation. Their large capacity allows operators to move significant amounts of coal in a single trip, minimizing the number of trips needed and thereby enhancing productivity on site.

Operational efficiency is further improved through the integration of modern technologies into haul truck operations. GPS systems, weight monitoring, and route optimization software help ensure that each truck is loaded to its maximum capacity while adhering to safety regulations. This technological support not only streamlines the transportation process but also helps to minimize fuel consumption and maintenance costs. By operating at peak efficiency, coal haul trucks contribute to a more sustainable and cost-effective mining operation, ultimately benefiting the overall productivity and profitability of the coal mining sector.

| Dimension | Value |

|---|---|

| Truck Model | CAT 797F |

| Payload Capacity | 400 tons |

| Engine Power | 4000 HP |

| Average Speed | 40 km/h |

| Fuel Capacity | 6,000 liters |

| Operating Weight | 684,000 lbs |

| Turn Radius | 9.96 m |

| Daily Operating Hours | 16 hours |

| Average Daily Load | 3,200 tons |

| Maintenance Interval | 250 hours |

Safety is paramount in the operation of haul trucks in coal mines, given the complexity of the environment and the machinery involved. Operators must be trained in the specific safety protocols associated with haul truck operation. These protocols typically include pre-operational inspections to ensure that all systems are functioning correctly, as well as the adherence to speed limits within the mine site to minimize the risk of accidents. Effective communication between operators and ground personnel is critical, often facilitated through the use of radios or visual signals to alert others about the truck's movements.

Additionally, best practices for haul truck operation encompass the establishment of safe travel routes and proper loading techniques to prevent overloading. Situational awareness is crucial; operators need to stay alert to the evolving conditions of the mine, including the presence of other vehicles, pedestrians, and changes in terrain. Regular training sessions and drills also help reinforce safety behaviors and ensure that all personnel are up-to-date with the latest safety standards and practices. By focusing on these aspects, mines can enhance operational efficiency while prioritizing the health and safety of all employees.

Haul trucks play a pivotal role in modern mining operations, serving as the primary means of transporting bulk materials from the excavation site to processing plants or waste dumps. These robust vehicles are designed to navigate the challenging terrains of mining sites, facilitating the efficient movement of minerals, coal, and other resources. With capacities ranging from 30 tons to over 400 tons, haul trucks are essential for optimizing the logistics of large-scale mining projects.

The significance of haul trucks in the industry is underscored by the statistics demonstrating their operational efficiency. For instance, in open-pit mining, haul trucks can account for up to 50% of the total operational cost, yet they are crucial for maintaining productivity. On average, haul trucks can cycle multiple trips per hour, significantly reducing the time needed for material transportation. This efficiency not only boosts the overall output of mining operations but also contributes to cost savings, making them indispensable in achieving both production targets and economic viability in the competitive mining sector.