Choosing the right Underground Haul Truck is crucial for successful mining operations. These trucks must handle tough terrain and heavy loads. Selecting the wrong model can lead to inefficiencies and increased costs.

Consider factors like payload capacity and haulage distance. The terrain can greatly influence performance. For example, a steep gradient may require a more powerful truck. Smaller sites may benefit from more compact models.

Reflect on maintenance and operational costs too. Some trucks may seem affordable initially but require costly repairs. Think about the long-term investment. Balancing short-term needs with future demands is essential. Each decision impacts productivity and safety in the mining environment.

Underground haul trucks play a crucial role in mining operations. They transport materials efficiently from the depths of the mine to the surface. This task is essential for maintaining a smooth workflow. Without reliable haul trucks, production could slow significantly.

Choosing the right truck can be challenging. Different mines have unique requirements. Factors like tunnel width, payload capacity, and terrain can influence the decision. It's important to consider the operational environment. Trucks must navigate tight corners and uneven ground. Sometimes, what seems ideal may not perform as expected.

Understanding maintenance needs is also key. Underground haul trucks endure tough conditions. Regular check-ups are vital to avoid unexpected downtime. A well-maintained truck improves safety and efficiency. Yet, many operators overlook this aspect. Relying solely on the truck’s specifications can lead to regrets later. Careful thought and planning are necessary for optimal results.

Selecting the right underground haul truck is crucial for mining operations. You should consider several key factors when making your choice. Payload capacity is one of the most important aspects. A truck with insufficient capacity can lead to increased trips and wasted time. Reports show that productivity can drop by up to 30% with inadequate hauling capacity.

Another factor to consider is the truck's maneuverability in tight spaces. Underground environments often have narrow tunnels and ramps. A truck that is too large can struggle in these areas, causing potential delays. In many cases, operational efficiency hinges on the ability to navigate smoothly.

Additionally, assess the truck's fuel efficiency. According to industry data, a more fuel-efficient truck can reduce operational costs by approximately 15%. However, the upfront cost of such trucks may be higher. It's important to weigh these factors against your long-term budget. Reflect on the trade-offs involved and the specific needs of your mining projects.

When selecting an underground haul truck, understanding the types available is crucial. Different trucks cater to specific mining needs, such as payload capacity and maneuverability. For example, smaller trucks are ideal for narrow tunnels, while larger models can handle high-capacity loads. A recent industry report highlighted that trucks with a payload capacity ranging from 20 to 40 tons are the most popular in underground operations. They effectively balance size and productivity.

Consider the drive type. Some trucks are equipped with electric drives, while others use diesel engines. Electric trucks are generally quieter and produce less emissions, making them suitable for underground environments. However, their upfront cost can be higher. A survey indicated that about 35% of mines are shifting toward electric options, reflecting a growing trend for sustainability.

It’s important to assess operational costs as well. Maintenance, fuel efficiency, and downtime all influence the total cost of ownership. Some reports suggest that maintenance can account for 30% of operational expenses. Many companies overlook this factor when making a purchase. Evaluating these aspects thoroughly can lead to better long-term decisions. Understanding the nuances of each truck type is essential for meeting your specific mining needs effectively.

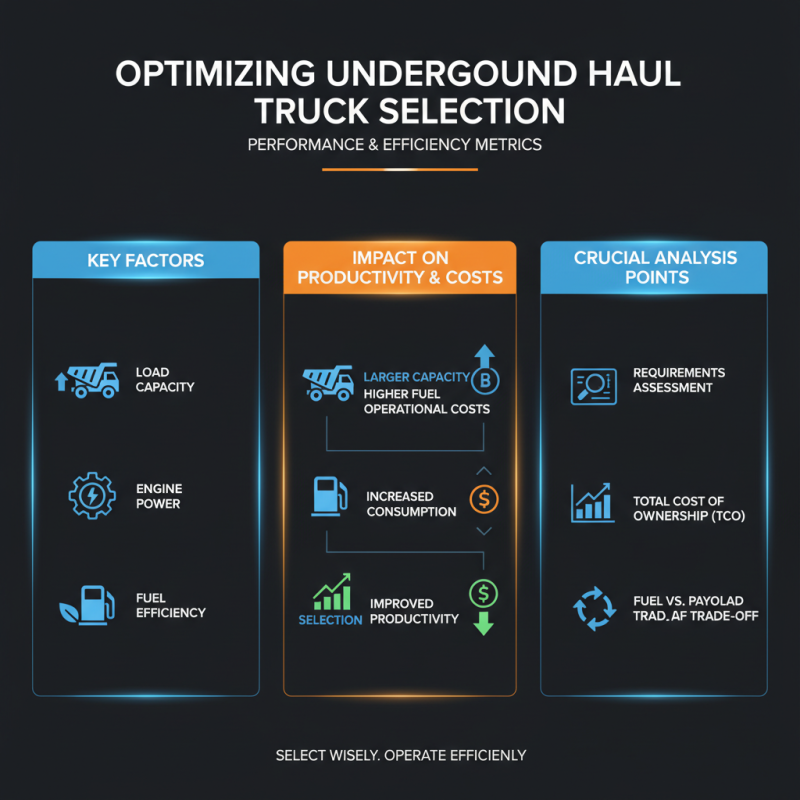

Selecting the right underground haul truck is crucial for mining operations. Understanding the performance and efficiency metrics can significantly impact productivity. Factors such as load capacity, engine power, and fuel efficiency should be analyzed. Trucks with larger capacities may seem ideal, but they often consume more fuel. This can lead to higher operational costs, negating any advantage.

Incorporating advanced technologies is another avenue to increase efficiency. Look for trucks equipped with automatic transmission systems. These systems can optimize gear shifts based on load and terrain. However, not all technologies are equally effective. Some features may complicate operations instead of simplifying them. Operators must adapt to these changes, which may take time.

Regular maintenance is vital for sustaining performance. Neglecting minor issues can escalate, leading to larger failures. This can affect overall efficiency. Monitoring tire performance can offer insights into potential problems. Additionally, the weight distribution affects the truck’s maneuverability and speed. Operators should routinely consider these aspects for optimal operation.

Maintaining underground haul trucks is crucial for mining operations. Regular service checks enhance truck performance and reduce downtime. Industry data shows that efficient maintenance can increase a truck’s lifespan by up to 50%. This ensures consistent productivity in often challenging environments.

Proper training for maintenance staff is essential. Having knowledgeable personnel can prevent costly mistakes. Reports indicate that companies with skilled technicians experience 30% fewer breakdowns. It's a significant factor when considering long-term costs. Additionally, incorporating predictive maintenance systems can proactively address issues before they escalate.

Parts availability is another consideration. Delays in acquiring components can halt operations. Establishing strong supplier relationships ensures access to quality parts. Many mines report that sustaining parts stock can reduce unexpected downtime by 40%. It’s a constant challenge to balance inventory with demand. Mining companies must reflect on their processes and address these gaps to improve overall efficiency.