Choosing the right equipment is crucial for optimizing productivity and efficiency in underground mining operations. One of the most significant components of this equipment lineup is the Underground Mining Truck. These specialized vehicles are designed to transport materials, ore, and waste within the unique and challenging environment of underground mines. With advancements in technology and an increasing array of options available in the market, selecting the best Underground Mining Truck has become a vital decision for operators aiming to enhance their operational capabilities.

In this guide, we will explore the essential factors to consider when choosing an Underground Mining Truck suitable for your specific operations. From assessing load capacity and maneuverability to examining fuel efficiency and maintenance requirements, understanding these key elements will enable you to make an informed choice. Furthermore, we will discuss how these trucks contribute to the overall safety and productivity of mining activities, highlighting the importance of investing in the right vehicle. By the end of this exploration, you will be better equipped to determine which Underground Mining Truck aligns with your operational needs and goals.

When selecting the best underground mining truck for your operations, it is crucial to understand the unique requirements that stem from the challenges of underground environments. With the global underground mining equipment market projected to reach approximately $28 billion by 2025, as reported by several industry analyses, choosing the right truck significantly influences operational efficiency and safety. Factors such as payload capacity, maneuverability in confined spaces, and robustness against challenging conditions must be at the forefront of decision-making.

The specific characteristics of underground mining operations include varying tunnel dimensions, ground conditions, and the need for high-efficiency hauling systems. Reports indicate that underground trucks typically need to handle payloads ranging from 15 to 65 tons, with optimal power-to-weight ratios that enhance mobility without compromising stability. Additionally, trucks must be designed to operate within restrictive height and width limitations, often at elevations where air quality and ventilation are major concerns. These operational specifics necessitate equipment that not only withstands harsh environments but also minimizes downtime and maintenance costs, which can significantly impact overall productivity in underground mining scenarios.

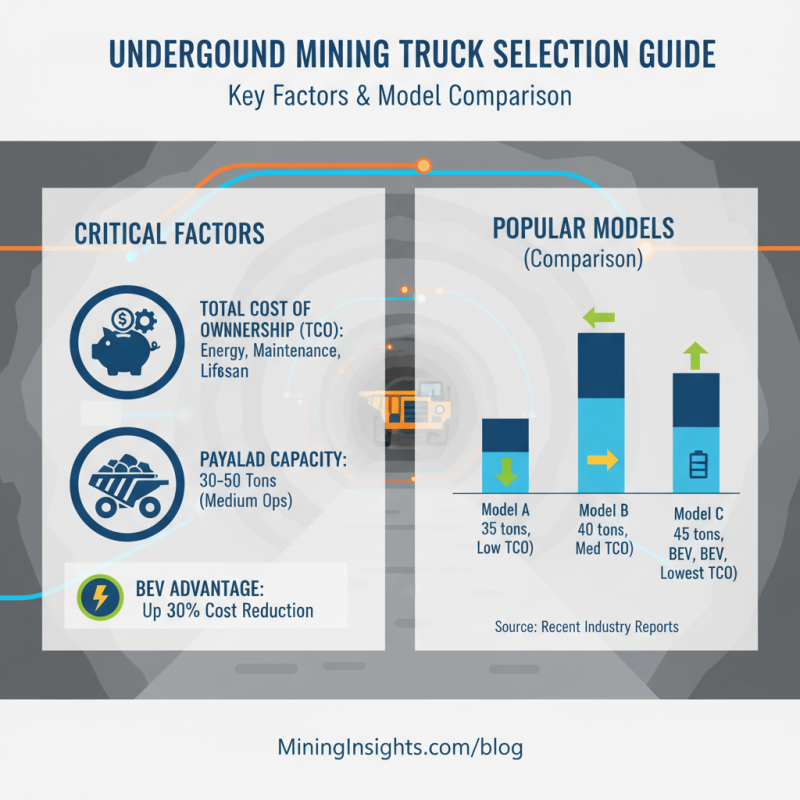

This bar chart illustrates the comparison of various specifications for underground mining trucks, which are crucial for understanding the best options available for mining operations in 2025.

When selecting the best underground mining truck for your operations, several key features should be taken into account to ensure efficiency and safety. Firstly, payload capacity is crucial. The truck must be able to carry the required load while maintaining stability in confined underground spaces. Operators should also consider the vehicle's maneuverability; a compact design allows for easier navigation through tunnels and around obstacles.

Additionally, the underground mining truck must have robust safety features. Look for models equipped with advanced braking systems, rollover protection, and environmental controls that promote operator comfort and safety. Effective ventilation is another significant aspect, as it helps to maintain air quality in the enclosed environment of a mine.

**Tips**: Always prioritize trucks with proven reliability in similar operational conditions. Conduct thorough research and consider feedback from current users to gauge performance and durability. Finally, evaluate the ease of maintenance; accessible parts can minimize downtime and enhance productivity in your mining operations.

| Feature | Description | Importance | Performance Rating (1-5) |

|---|---|---|---|

| Load Capacity | The maximum weight that the truck can transport efficiently. | High | 5 |

| Maneuverability | Ability to navigate tight spaces and rough terrain. | Medium | 4 |

| Engine Power | The horsepower of the engine affects speed and efficiency. | High | 5 |

| Safety Features | Includes roll-over protection and visibility enhancements. | Critical | 5 |

| Fuel Efficiency | How much fuel the truck consumes per operation hour. | High | 4 |

| Maintenance Requirements | Frequency and ease of maintenance tasks. | Medium | 3 |

When it comes to selecting the best underground mining truck for your operations, a comparative analysis of popular models is essential. Recent industry reports highlight that the total cost of ownership (TCO) and payload capacity are critical factors to consider. For example, models that can carry between 30 to 50 tons are generally preferred for medium-sized operations, providing a good balance between productivity and maneuverability in confined spaces. Additionally, advancements in battery electric vehicles (BEVs) are fueling interest, with many operations seeing a potential reduction in operational costs by up to 30% due to lower energy consumption and reduced maintenance needs.

Tip: Always consider the terrain and specific needs of your mine when choosing a truck model; a truck's suspension and powertrain will significantly impact its performance in varying conditions.

Another important aspect is the availability of parts and service support. Industry studies indicate that downtime due to maintenance can severely affect productivity, with some operations reporting losses exceeding $1 million per year. Therefore, selecting a model from a manufacturer known for reliable service and readily available parts could be invaluable. An examination of user feedback can also provide insights into long-term performance and reliability, helping you make an informed decision.

Tip: Create a checklist of key features crucial to your operations, like payload capacity, fuel efficiency, and service intervals, before finalizing your selection to ensure all operational needs are met.

When evaluating the cost-effectiveness and long-term value of underground mining trucks, several critical factors come into play. First and foremost, the initial purchase price of the truck must be considered in relation to its operational efficiency. Advanced technology in modern mining trucks often translates to better fuel efficiency and lower maintenance costs, which can significantly reduce the total cost of ownership over time. Buyers should analyze the expected performance and durability of the truck to ensure that the investment will yield returns that justify its upfront cost.

Moreover, assessing the long-term value involves understanding how the chosen truck will integrate with existing mining operations. Features such as load capacity, adaptability to various terrains, and ease of maintenance are essential. A truck that can efficiently handle different types of materials and work in challenging conditions will not only enhance productivity but also contribute to reduced downtime. Additionally, considering the availability of spare parts and support services can further impact the truck's value, making it a crucial aspect of long-term cost considerations. Ultimately, a thorough evaluation of these factors will aid in making an informed decision that balances upfront costs with future operational savings.

When selecting the best underground mining truck for your operations, considering maintenance and support services is crucial. Reliable maintenance extends the life of your equipment, reduces downtime, and ultimately saves costs. Ensure that the service provider has a comprehensive maintenance program that includes regular inspections, prompt repairs, and availability of spare parts. A well-structured maintenance plan will help you keep your trucks in optimal working condition, allowing for smooth operations in the challenges of underground environments.

Tips: Regularly train your maintenance team on the latest technologies and best practices. This not only enhances their skills but also promotes a proactive approach to equipment care. Additionally, maintain a detailed log of all maintenance activities, as this documentation can help identify patterns in repairs and preventative measures.

Choosing a truck with accessible support services is equally important. Evaluate the availability of technical assistance, whether on-site or remotely, and ensure that the support network can address potential issues quickly. Quick response times can dramatically reduce the impact of operational disruptions, allowing your mining operations to continue without significant delays.

Tips: Establish a close relationship with your service provider to foster better communication. This rapport can lead to quicker resolutions during emergencies and tailored support that aligns with your specific operational needs.