Choosing the right Mining Rock Truck is crucial for any mining operation. Renowned industry expert John Doe once said, "The right equipment can make all the difference in efficiency." This statement reflects the significant impact of selecting the appropriate truck for specific needs.

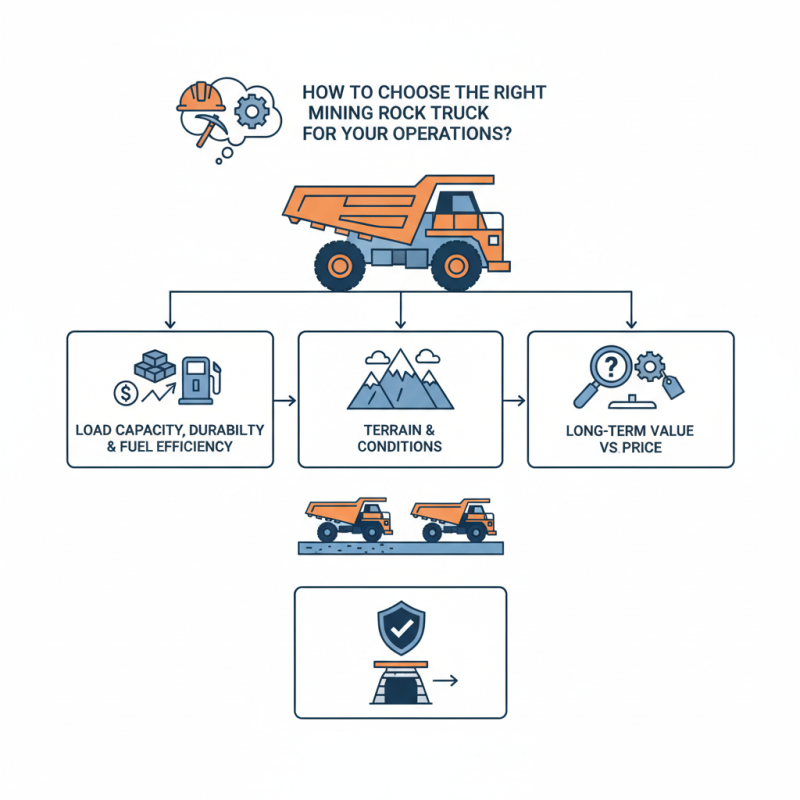

When considering a Mining Rock Truck, factors such as load capacity, durability, and fuel efficiency are vital. The right truck can enhance productivity and reduce costs. However, many operators overlook these details. They often prioritize price over long-term value. This can lead to regrettable choices that affect overall performance.

Moreover, understanding the terrain and conditions is essential. Different trucks serve various environments. Some are better suited for rough, uneven terrain. Others excel in flat, stable areas. Recognizing these differences can help avoid future challenges. Operators must reflect on their unique situations before making a decision. The choice feels overwhelming at times, but evaluating key features thoroughly can pave the way for success.

When choosing a mining rock truck, understanding the different types is essential. There are several options available, each designed for specific conditions. The two primary categories are articulated trucks and rigid haul trucks. Articulated trucks are known for their flexibility. They handle rough terrains better than others. This makes them ideal for smaller operations.

Rigid haul trucks are typically larger. They are built for high capacity and long-distance hauling. However, they require stable surfaces to operate efficiently. For operations located in challenging environments, articulated trucks might be the better choice. But remember, their payload capacity is usually lower. This can affect the overall efficiency of your operation.

Often, operators overlook the importance of maintenance. Regular check-ups can prolong the life of these machines. Choosing the right type of truck should involve assessing the specific needs of your site. Take time to evaluate load size, distance, and terrain. This reflective process can lead to better decisions and ultimately improve productivity.

| Truck Type | Payload Capacity (tons) | Engine Power (HP) | Max Speed (km/h) | Terrain Suitability |

|---|---|---|---|---|

| Articulated Dump Truck | 30 - 40 | 250 - 450 | 40 | Rough Terrain |

| Rigid Dump Truck | 40 - 100 | 400 - 750 | 50 | Flat Terrain |

| Underground Truck | 10 - 20 | 100 - 250 | 20 | Underground |

| Mini Dump Truck | 5 - 10 | 50 - 150 | 30 | Restricted Spaces |

When selecting a mining rock truck, it's essential to thoroughly assess your operational requirements. This begins with understanding the terrain. Is it rugged or relatively flat? Trucks suited for steep inclines often have different specifications compared to those for flat surfaces. This factor greatly influences the truck's capacity and mobility.

Another crucial aspect is load capacity. How much material do you need to transport in a single trip? While higher capacities are beneficial, they may not be feasible for all operations. It’s important to balance capacity with the truck’s maneuverability. Consider potential congestion points in your operational layout. A larger truck may struggle in tight spaces, which could lead to delays.

Fuel efficiency is also essential. High fuel consumption can significantly increase operational costs. Monitor the fuel usage over time and adjust your choice based on the average distance traveled. However, calculating fuel use can be tricky. Assessing the cost-effectiveness of different models often requires hands-on experience. This evaluation is subjective and can vary depending on individual operations.

Choosing the right mining rock truck is crucial for optimizing operations. The right features can significantly impact productivity. Consider payload capacity. This determines how much material the truck can carry. For larger operations, a higher payload is often more efficient. But, smaller operations may not need such heavy-duty trucks. Balance is key.

Another important factor is fuel efficiency. A truck that consumes less fuel can save substantial costs over time. Look at operational costs, not just the truck's purchase price. Think about maintenance needs too. Trucks with simpler designs are generally easier to service, saving you time and money in the long run.

Tip: Always check the turning radius. A truck that can maneuver easily is vital in tight spaces. Also, don’t overlook the driver's comfort. Features like ergonomic seating can enhance productivity.

Finally, don't forget about technology. Many modern trucks come with advanced sensors and data tracking. While this can be beneficial, be aware of the potential learning curve for staff. Investing in training might be necessary. Balancing technology with usability is an ongoing challenge.

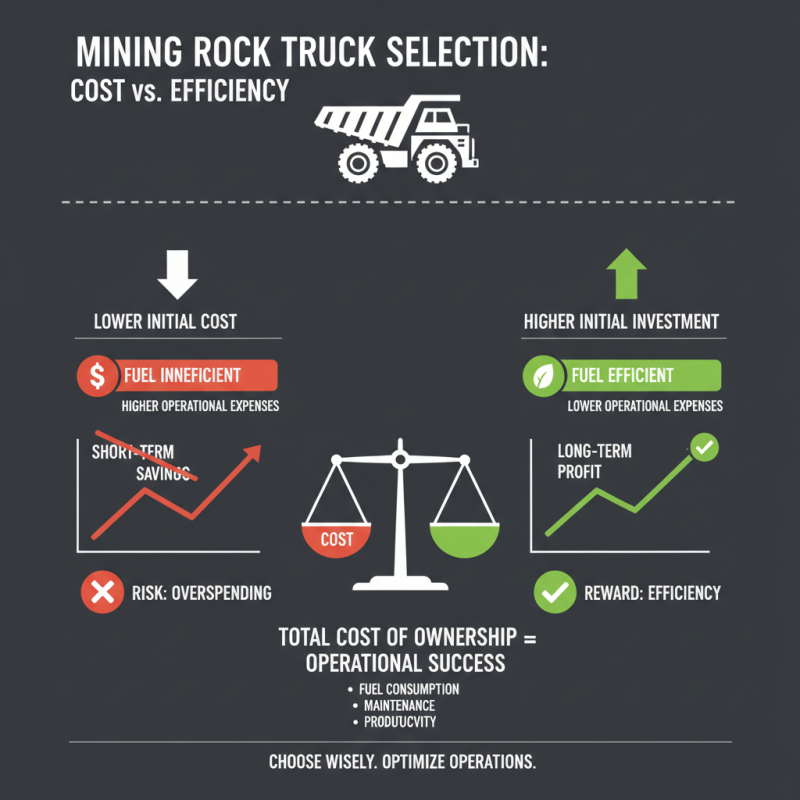

Choosing the right mining rock truck is crucial for operational success. Evaluating cost versus efficiency is a critical step. Many operators focus solely on price, overlooking long-term benefits. A truck with a lower initial cost might consume more fuel, leading to higher overall expenses. Consider the total cost of ownership, which includes maintenance and operational efficiency.

Tips: Assess fuel consumption early. More efficient models can save money over time. Evaluate how often the truck will be used. If it runs continuously, efficiency becomes even more essential.

Think about each truck's payload capacity and the terrain. Heavy loads on rugged terrain can lead to wear and tear. Evaluate the repair records for different models. Some trucks may appear cheaper but incur higher repair costs. Always ask operators about their experiences and insights. There is value in real, hands-on feedback.

Owning a mining rock truck requires careful thought about maintenance needs. Routine checks are essential. Oil changes, tire inspections, and brake assessments should be part of your schedule. Often, operators overlook basic maintenance, leading to costly repairs.

Training your team on proper upkeep is vital. Employees should understand the significance of regular inspections. Misunderstanding simple procedures can lead to bigger problems down the road. Keeping a detailed maintenance log helps track issues early. It's easy to miss small signs when focus shifts.

Support services also matter a great deal. Be aware of local resources and specialists. They can assist with troubleshooting and repairs. Relying solely on in-house teams may not be sufficient. Some challenges require expert insight. Balancing between self-reliance and external help is key to longevity in operations. Neglecting support can lead to unexpected downtime.