The underground haul truck is a pivotal machine in the mining industry. In 2026, these trucks have evolved to meet increasing demands. Features such as advanced safety systems and enhanced payload capacities are crucial. The focus is not only on efficiency but also on operator comfort.

Modern underground haul trucks incorporate smart technology. This includes real-time monitoring systems that boost productivity. However, challenges remain. Maintenance can be complex and costly, affecting operations. Operators must adapt to new technologies. It takes time to learn how to use these advanced features effectively.

Beyond technology, the environmental impact of these trucks should be considered. Fuel efficiency is a key concern as regulations tighten. As we look at the benefits, it's vital to reflect on areas for improvement. The 2026 underground haul truck represents progress but also poses new questions for the industry.

The features of the best underground haul trucks for 2026 focus on efficiency and safety. Recent industry reports indicate a growing demand for trucks with advanced automation systems. These systems reduce operator fatigue and increase operational safety by making real-time adjustments.

A vital aspect is energy efficiency. The latest data shows that trucks utilizing alternative fuel sources can achieve up to 30% more efficiency compared to traditional models. This shift not only lowers emissions but also enhances overall operational costs. Operators are also looking for enhanced payload capacities. Models that support higher loads can significantly improve productivity in underground transport operations.

Another key feature is improved maneuverability. Many underground haul trucks now boast tighter turning radii and flexible suspensions. These enhancements are crucial in navigating the confined spaces of underground environments. However, maintenance remains a challenge. The complexity of modern machines can lead to unexpected downtime. Operators need to balance advanced features with maintenance feasibility to ensure consistent performance in harsh conditions.

The latest advancements in underground haul truck technology are transforming the mining industry. A recent industry report highlights that these trucks can improve efficiency by up to 30%. This boost comes from enhanced payload capacities and superior navigation systems. Operators benefit from real-time data analytics, which helps optimize routes and reduce downtime.

Another significant feature is the integration of autonomous capabilities. Trucks equipped with autonomous features can operate with minimal human intervention. According to market studies, this decreases the risk of accidents by nearly 40%. However, the reliance on technology raises questions about training needs for human operators. Operators must adapt to oversee these advanced systems, balancing between automation and essential skills.

Energy efficiency is a critical focus for new designs. Many models now use hybrid or fully electric powertrains. These innovations can cut fuel costs by 25%. Yet, transitioning to new technology can be challenging. Not all mines have the necessary infrastructure to support electric charging or maintenance needs. This highlights a gap where further improvements are still required.

Underground haul trucks are essential for mining operations. They transport materials efficiently in challenging environments. Evaluating different models helps operators choose the right fit.

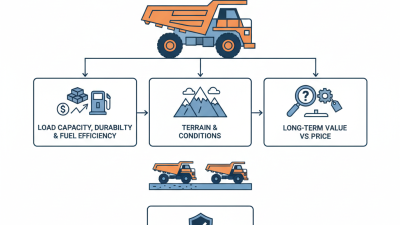

Many leading models offer high payload capacities. Their robust designs enhance durability in harsh conditions. Some feature advanced safety systems, minimizing risks for operators. However, the cost of these trucks can be significant. Operators must consider maintenance and fuel efficiency as well.

Comparing models highlights various strengths and weaknesses. Some trucks may excel in navigating tight spaces, while others focus on speed. Factors like turning radius and lifting capability are crucial. There is no one-size-fits-all solution. Each operation has unique needs. Therefore, choosing the right truck requires careful analysis and reflection on operational demands.

| Model | Load Capacity (tons) | Engine Power (HP) | Dimensions (L x W x H, m) | Fuel Efficiency (L/100km) | Key Features |

|---|---|---|---|---|---|

| Model A | 30 | 400 | 7.5 x 3.0 x 3.2 | 20 | High durability, Advanced control system |

| Model B | 28 | 350 | 7.0 x 2.8 x 3.1 | 22 | Compact design, Enhanced safety features |

| Model C | 32 | 450 | 8.0 x 3.5 x 3.4 | 18 | High performance, Eco-friendly options |

| Model D | 35 | 500 | 8.5 x 3.8 x 3.5 | 17 | Robust design, Low operating costs |

In 2026, safety innovations in underground haul trucks take center stage. Advanced sensors detect obstacles in real-time. This allows for safer navigation in tight, dark spaces. Truck operators can react quickly to sudden hazards, reducing accident risks. Enhanced visibility systems, including LED lighting, improve sightlines. Operators can now see potential dangers more clearly.

Another notable innovation is the implementation of automated braking systems. These systems engage automatically when detecting an impending collision. This technology alleviates some pressure from drivers. However, dependence on automation raises concerns about human oversight. Operators must remain vigilant, despite these advancements.

Moreover, the integration of communication systems enables better coordination among trucks. Real-time updates on route changes can prevent bottlenecks. Yet, reliance on technology can be flawed; systems may malfunction under adverse conditions. Operators must be prepared for such scenarios. Addressing these potential issues strengthens safety protocols. The future of underground haul trucks looks promising, yet there’s room for improvement.

The environmental impact of modern haul trucks is becoming increasingly significant. These vehicles are essential in mining and construction, yet their operation can lead to high emissions. Recent studies show that conventional trucks emit over 1,000 tons of CO2 annually. This is a staggering figure for industries striving for sustainability.

Modern underground haul trucks increasingly incorporate eco-friendly features. Electric and hybrid systems reduce emissions and noise pollution. A recent report indicated that replacing diesel engines with electric alternatives can reduce CO2 emissions by up to 50%. Such advancements improve air quality and support greener mining practices.

Tips: Regular maintenance can enhance efficiency. Keep tires inflated and engines tuned. Small changes can lead to noticeable improvements. Tracking fuel consumption helps identify areas for efficiency gains. Adopting these practices can minimize costs and environmental impact. It's clear that while progress is being made, there's still a long way to go in optimizing the balance between productivity and sustainability in haul truck operations.