The mining industry plays a crucial role in global economies. It relies heavily on efficient transportation of materials. A key component in this process is the Mining Rock Truck. These trucks are designed to handle heavy loads and rugged terrains.

According to a recent industry report by Future Market Insights, the global market for mining trucks is expected to reach $4 billion by 2030. Their efficiency can significantly affect mining operations. Choosing the right Mining Rock Truck can lead to increased productivity and reduced operational costs. However, not all models meet the varied demands of the industry.

Many operators overlook essential features when selecting trucks. Some may prioritize cost over durability and performance. This can lead to increased maintenance and downtime. Reflecting on past decisions is essential. An informed choice on Mining Rock Trucks is vital for optimizing operations and sustaining growth in the competitive landscape.

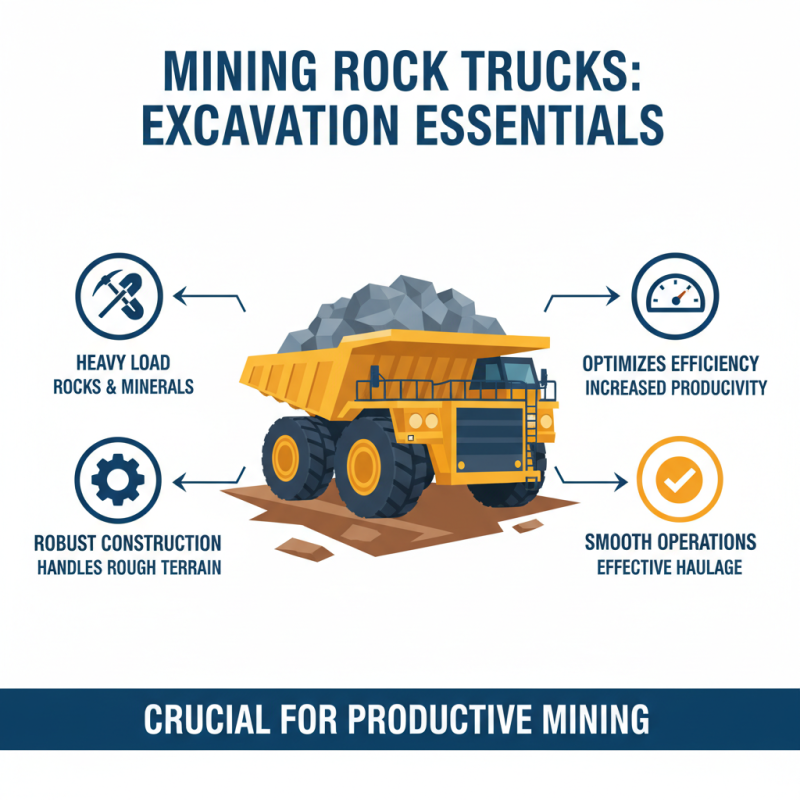

Mining rock trucks play a crucial role in excavation operations. These vehicles are specifically designed to transport heavy loads of rocks and minerals. Their robust construction allows them to handle rough terrains, making them essential in mining sites. The efficiency of these trucks can significantly affect overall productivity. When loads are transported effectively, operations run smoothly.

However, not all rock trucks are equally efficient in every scenario. The selection of an appropriate model often depends on the specific needs of the site. Variations in terrain, load types, and operational scale can challenge operators. Some models may excel in maneuverability but lack payload capacity. Others might carry heavy loads but struggle on uneven surfaces.

Operators must assess their requirements carefully. Understanding the balance between capacity and terrain adaptability is vital. It's also important to regularly evaluate the performance of the truck model in use. This involves monitoring factors such as fuel efficiency and maintenance costs. Often, what works well initially may require reassessment as operations evolve. Continuous reflection can lead to improved choices for future projects.

When choosing a mining rock truck, several key features demand attention. Load capacity is crucial. Ensure the truck can handle the volume of material you typically transport. A capacity of 40 tons might suit smaller operations. Larger sites may need trucks over 100 tons. It’s vital to match capacity with your operational needs.

Next, consider the truck's maneuverability. Mining sites can be rough and restricted. A truck with a tight turning radius will navigate easily in narrow spaces. Look for trucks with good suspension systems. They reduce wear and tear on the vehicle, which can lead to lower maintenance costs.

Don't forget about fuel efficiency. Operating costs can skyrocket without careful planning. A fuel-efficient model can save money in the long run. Finally, ensure the truck has safety features. Roll-over protection and excellent visibility are essential. These features not only protect your crew but also reduce the risk of accidents. Evaluate each option carefully, as selecting the wrong rock truck can lead to operational setbacks.

When choosing mining rock trucks, it is essential to consider the specific operations. Different models excel in varying conditions. For example, in wet and muddy environments, large tires provide better traction. They maintain stability and improve efficiency on slippery surfaces. However, these trucks may struggle on rocky or uneven terrain.

Some models focus on high payload capacity. They transport more material per trip, enhancing overall productivity. Yet, heavy loads can lead to mechanical issues if not properly maintained. Regular inspections are crucial to ensure these trucks operate smoothly. Ignoring preventive maintenance can be costly in the long run.

Other options may prioritize maneuverability. Smaller trucks are easier to navigate in confined spaces. They can enter tight spots that larger models cannot reach. However, this sometimes means sacrificing payload capacity. Each operation is unique, requiring careful consideration of these factors. Understanding the strengths and limitations of each model is vital for optimizing mining operations.

| Model | Load Capacity (tons) | Engine Power (HP) | Weight (tons) | Wheelbase (m) |

|---|---|---|---|---|

| Model A | 40 | 400 | 25 | 4.5 |

| Model B | 50 | 450 | 30 | 5.0 |

| Model C | 60 | 500 | 35 | 5.5 |

| Model D | 70 | 550 | 40 | 6.0 |

| Model E | 80 | 600 | 45 | 6.5 |

When selecting mining rock trucks, the decision can be overwhelming. Various models offer different capabilities and features. It's essential to analyze brands based on efficiency, durability, and cost-effectiveness. Some models excel in tight spaces while others are designed for heavy loads on rugged terrains.

Tips: Consider the types of materials you’ll be transporting. Different trucks are suitable for different materials, from loose gravel to heavy boulders. This can greatly affect your productivity.

Some mining rock trucks are praised for their fuel efficiency. However, their performance in harsh environments may be lacking. It's crucial to evaluate whether you prioritize fuel savings over durability. Not every model withstands extreme conditions equally well. Sometimes, it’s tempting to choose the cheapest option without realizing the long-term costs.

Tips: Assess maintenance requirements. Some trucks require frequent servicing, which can add to operational costs. Understand the trade-offs between initial investment and ongoing expenses. This reflection can lead to better decisions.

This chart compares the load capacity of various mining rock truck models. It helps in determining which model may be best suited for specific operational needs.

The future of mining rock truck technology is rapidly evolving. Increased automation, electric propulsion, and data analytics are redefining efficiency in operations. According to a recent industry report, electric mining trucks could reduce operational costs by up to 50%. Companies are focused on sustainable practices that cut emissions and lower the carbon footprint.

One key trend is telematics. Real-time data on vehicle performance enhances decision-making. Operators can track fuel usage and maintenance needs more accurately. This leads to reduced downtime and improved productivity. The integration of AI in predictive maintenance is also on the rise. It helps anticipate failures before they occur, increasing reliability.

Tips: When considering new models, assess the total cost of ownership. Evaluate energy sources, especially if aiming for sustainability. Always factor in how technology can improve safety and efficiency. Reviewing operational data periodically can highlight potential areas of improvement. Embracing these changes may be challenging, but it's necessary for staying competitive.