As the coal mining industry evolves, choosing the right Coal Mine Trucks becomes crucial. These trucks play a vital role in transporting coal efficiently. In 2026, factors such as durability, load capacity, and fuel efficiency will be essential in making the best choices.

The right Coal Mine Trucks should withstand harsh environments. They must handle heavy loads while maintaining reliability. It's important to consider specific features like tire durability and engine power. Trucks should also be designed for ease of maintenance. This helps minimize downtime during operations. However, many manufacturers might overlook these practical aspects.

Potential buyers should reflect on their needs and job requirements. Are you looking for high capacity or maneuverability? This choice can affect productivity. Investing in the best Coal Mine Trucks isn't just about cost; it's about long-term efficiency and performance.

When considering coal mining trucks for 2026, it's essential to understand the different types available. Haul trucks are typically larger and designed for heavy loads. They can carry significant amounts of coal over long distances. These trucks often have powerful engines and robust build to withstand tough mining environments. Smaller trucks, like utility vehicles, are used for transporting workers and tools around the site.

Electric trucks are gaining traction due to their lower emissions. They are a promising alternative to traditional fuel-powered trucks. However, the infrastructure for recharging them is still developing. Managing range anxiety in electric trucks is a concern. Moreover, hybrid options combine both electric and diesel power, offering versatility in operations.

Every type of coal mining truck has its pros and cons. Larger trucks can be inefficient in tighter spaces. Smaller ones may not handle heavy loads as effectively. Operators must assess their specific needs carefully. Investing in the right truck type can greatly impact productivity and operational costs. There is always room for improvement in efficiency and sustainability within the coal mining sector.

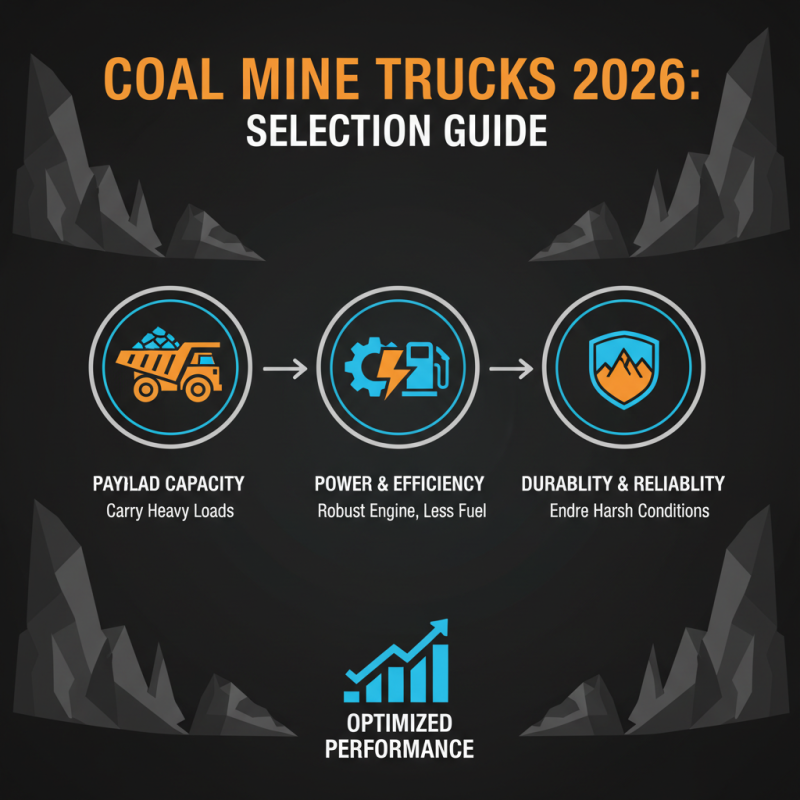

When selecting the best coal mine trucks for 2026, several key specifications matter. The payload capacity is crucial. It defines how much weight the truck can carry. Look for capacities that can handle heavy loads efficiently. A balance between power and fuel efficiency is vital. Trucks should offer robust engines capable of enduring harsh conditions while minimizing fuel usage.

Another important consideration is the truck's durability. Coal mining environments can be extreme. Materials used in construction should withstand wear and tear. Pay attention to the design features. Reinforced frames and heavy-duty tires are essential. Hydraulic systems should be reliable, as they impact performance directly.

Safety features are non-negotiable. Trucks need advanced braking systems and stability controls. Visibility during operations is key. Larger mirrors and well-placed lights can enhance safety. Comfort also plays a role. A well-designed cabin can reduce driver fatigue. However, many drivers still report discomfort over long shifts. Continuous improvement in these areas is necessary. Evaluating feedback from operators can lead to better designs.

The coal mining industry is rapidly evolving. Technological advancements are significantly impacting coal mine trucks. New designs focus on efficiency, safety, and environmental concerns. The Global Mining Truck Market Report indicates a projected growth rate of 4.5% annually through 2026.

Electric and hybrid trucks are gaining traction. They reduce emissions, leading to cleaner operations. Reports suggest that electric trucks can decrease operating costs by 20% compared to traditional diesel models. Integrating AI into fleet management is another key trend. Smart systems can analyze route efficiency, optimizing fuel usage.

However, challenges remain. Upfront costs for new technology can be high. Many mines hesitate to invest in new models without guaranteed returns. Furthermore, the transition from traditional trucks to new technology can disrupt operations. Training staff on new systems adds another layer of complexity. Each mine must evaluate its unique situation carefully. Balancing cost, safety, and efficiency will define the future of coal mine trucks.

| Feature | Description | Value |

|---|---|---|

| Payload Capacity | Maximum load the truck can carry | 200 tons |

| Fuel Efficiency | Amount of fuel consumed per mile | 7 miles per gallon |

| Engine Type | Type of engine used for better performance | Hybrid Diesel-Electric |

| Safety Features | Safety technologies included in the truck | Anti-lock Braking System, Roll-over Protection |

| Technological Integration | Smart technology for monitoring and control | IoT Connectivity, Remote Diagnostics |

| Maintenance Interval | Recommended frequency for maintenance checks | 3000 miles |

| Operational Cost | Average cost per mile to operate | $2.50 |

As the mining industry evolves, so do the environmental considerations surrounding coal mine trucks. Regulations are tightening. Companies must prioritize sustainability. This involves using vehicles that minimize emissions and reduce noise pollution. Electric and hybrid trucks are gaining traction. These alternatives offer a cleaner solution for coal transportation.

Tips for selecting eco-friendly trucks:

Another crucial factor is the compliance with local regulations. Every region may have different requirements. Staying informed about these standards is essential. This ensures operations are not only efficient but also environmentally responsible. Companies should also consider the lifecycle of vehicles from production to disposal. The environmental impact extends beyond fuel consumption.

Evaluating the overall impact of mining operations will lead to better practices. Reflecting on these choices can promote a sustainable future. Miners should not only focus on profits but also on the planet’s health.

When considering coal mine trucks for 2026, it's essential to evaluate the top manufacturers and their models. Choosing the right vehicle can enhance productivity and safety at the site. Leading manufacturers are focusing on fuel efficiency, payload capacity, and advanced safety features. Some models now feature improved suspension systems for rough terrain. This ensures a smoother ride over uneven surfaces.

However, not all models meet every requirement. Some trucks may lack the latest technology for emissions reduction. Additionally, maintenance access can vary significantly between designs. Operators might find certain models more challenging to service than others. It’s crucial to weigh these factors when assessing options.

Another aspect is driver comfort. A truck that is hard to operate can reduce efficiency. Cab design plays a vital role here. Spacious interiors and user-friendly controls are important. A combination of modern technology and simplicity often yields the best experience. Ultimately, the choice of coal mine truck should align with specific operational needs and site conditions.